TH9010 series is a multi-channel parallel scanning withstand voltage tester introduced by Tonghui Electronics with years of experience in the development of electrical safety test instruments. A single machine can measure 8 channels at the same time, and judge the test results by channel, which is equivalent to eight TH9310 working at the same time, which not only improves the testing efficiency of the production line, but also saves the space of the production line. At the same time, the instrument can be connected to the scanner way to expand an instrument up to 8 × 16 channels to meet the actual needs of customers.

| Summary parameters | TH9010 | TH9010A | |

| channel number | 8 | 4 | |

| Pressure resistance test | output voltage | AC: 5kV DC: 6kV | |

| Output Current | AC:10mA DC: 5mA | ||

| Insulation testing | output voltage | 0.1kV - 1kV | |

| Resistance Test Range | 0.1MΩ-10.0GΩ | ||

| Matching Scan Extender Models | TH90101 | TH90101A | |

| Scanner Channel Configuration | 8×4 | 4×4 | |

| Maximum number of channels | 128 | 64-way | |

Functional Features

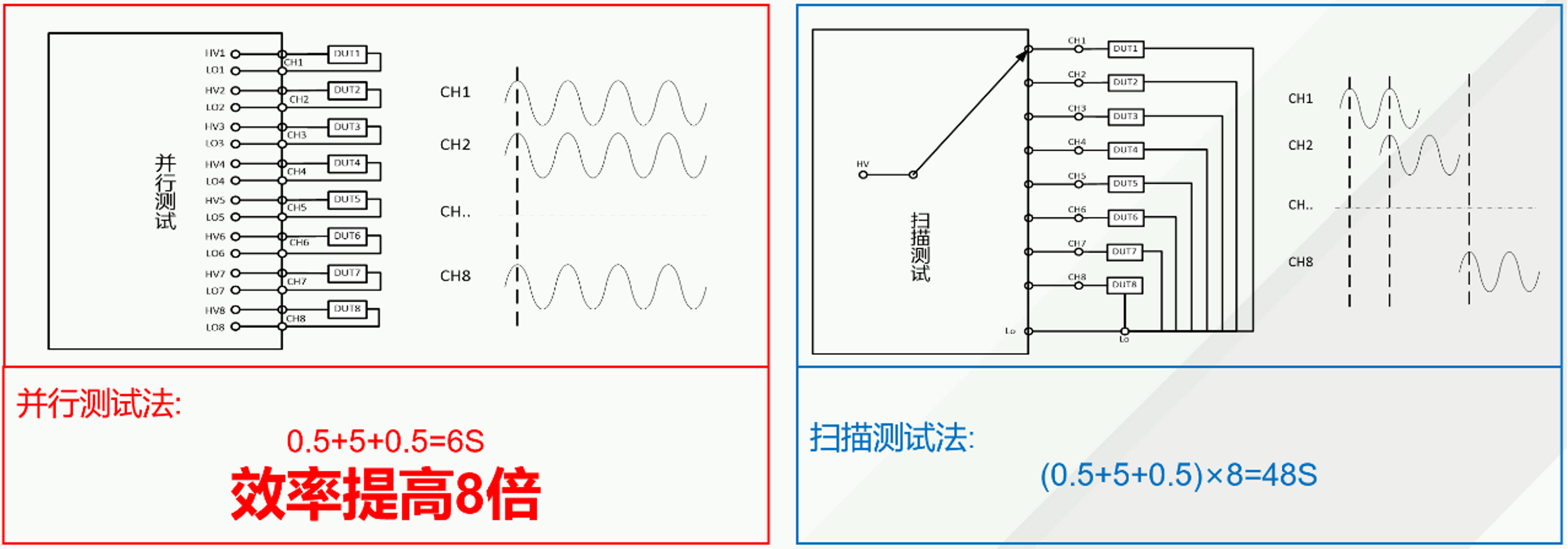

A. Synchronized test functions

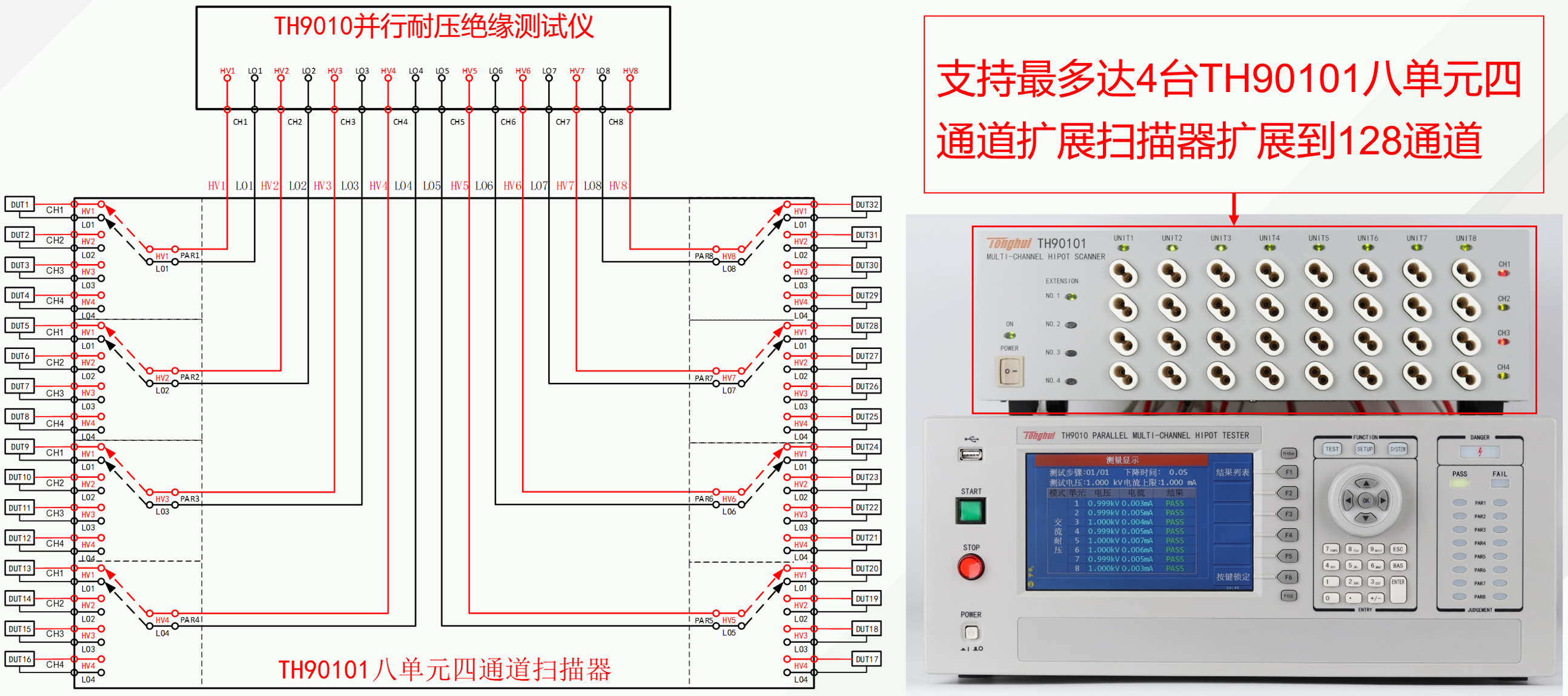

The 8 independent channels of the TH9010 series support synchronized parallel outputs, thereby increasing test efficiency by a factor of 8. With the special scanning expander TH90101, one channel can be expanded to 4 channels, and up to 4 stacked expander, the instrument can be expanded to 8 * 4 * 4 = 128 channels.

B. Electrocution protection function

When the operator is in contact with the high-voltage output, the instrument will monitor whether the current flowing through the human body is too high, and if it is determined to be electrocution, the instrument will immediately cut off the output to protect the user's safety.

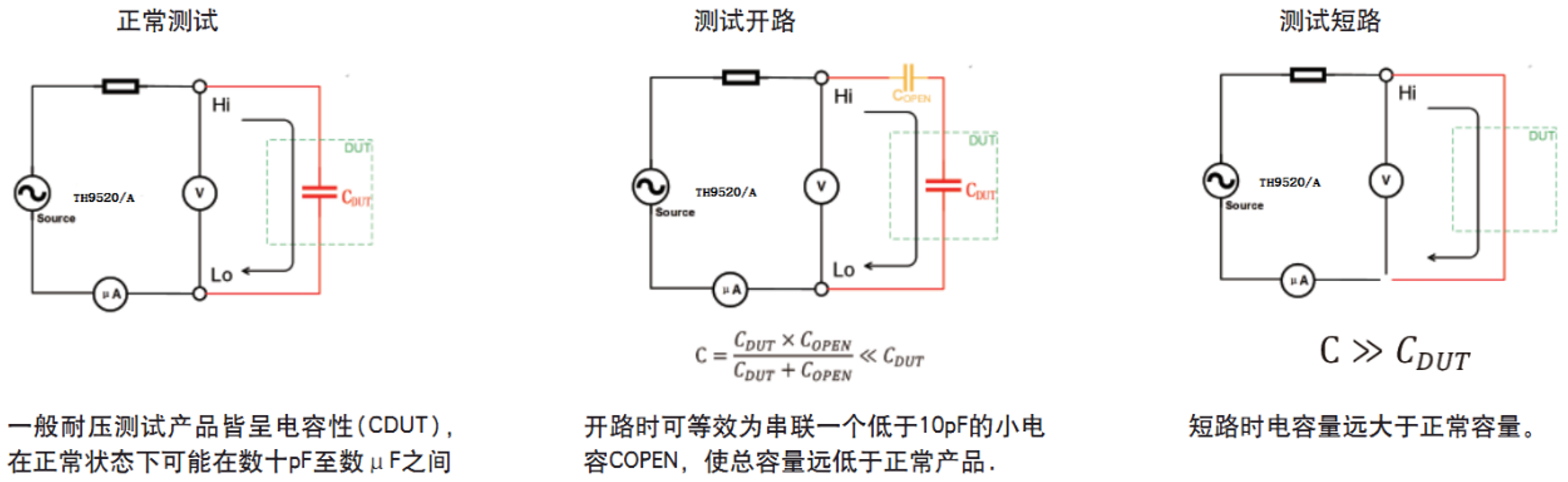

C. Open Short Circuit Detection Function (OSC)

In the process of voltage withstand test due to poor contact between the measured part and the test line, test line damage, etc., open-circuit phenomenon occurs, resulting in defective products misjudged as good products; damaged parts under test or the measured end of the spacing is too small, resulting in a short circuit of the test line phenomenon.

With the OCS function, the TH9520/A can detect open and short circuit conditions at the test end in advance, which reduces the occurrence of poor contact problems on the production line, protects fixtures and equipment, and saves test costs.

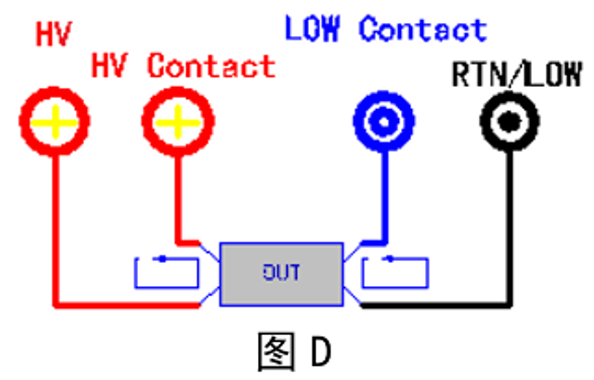

D. Contact inspection function

In addition to the OSC function, a pin detection function (Fig. D) is also available with an expander to ensure reliable connections between the DUT and the test line to improve test reliability and efficiency for contact checking during production line testing.

B. Arc detection function (ARC)

Poor voltage withstand refers to the occurrence of electrical flashover or insulation damage in the voltage withstand test. Nowadays, voltage withstand insulation test has become the standard equipment for all kinds of electrical equipment and insulation material safety test. However, just considering the insulation failure can not completely solve the product safety problems, another type of phenomenon, arc discharge ARC in the withstand voltage test is getting more and more attention, discharge and insulation capacity has a very high correlation between, so the ARC detection is the key to control the quality of the product.

Arc discharge occurs in the following two cases:

a) When the material is subjected to high voltage and the electric field strength is greater than the ionization energy of the gas, the gas on the surface of the material will undergo transient ionization phenomenon, which will result in the formation of flames on the surface of the material and the formation of temperature rise phenomenon on the material. Prolonged ignition and temperature rise may result in a qualitative change of the material, leading to insulation deterioration, a decrease in voltage tolerance, and ultimately insulation failure.

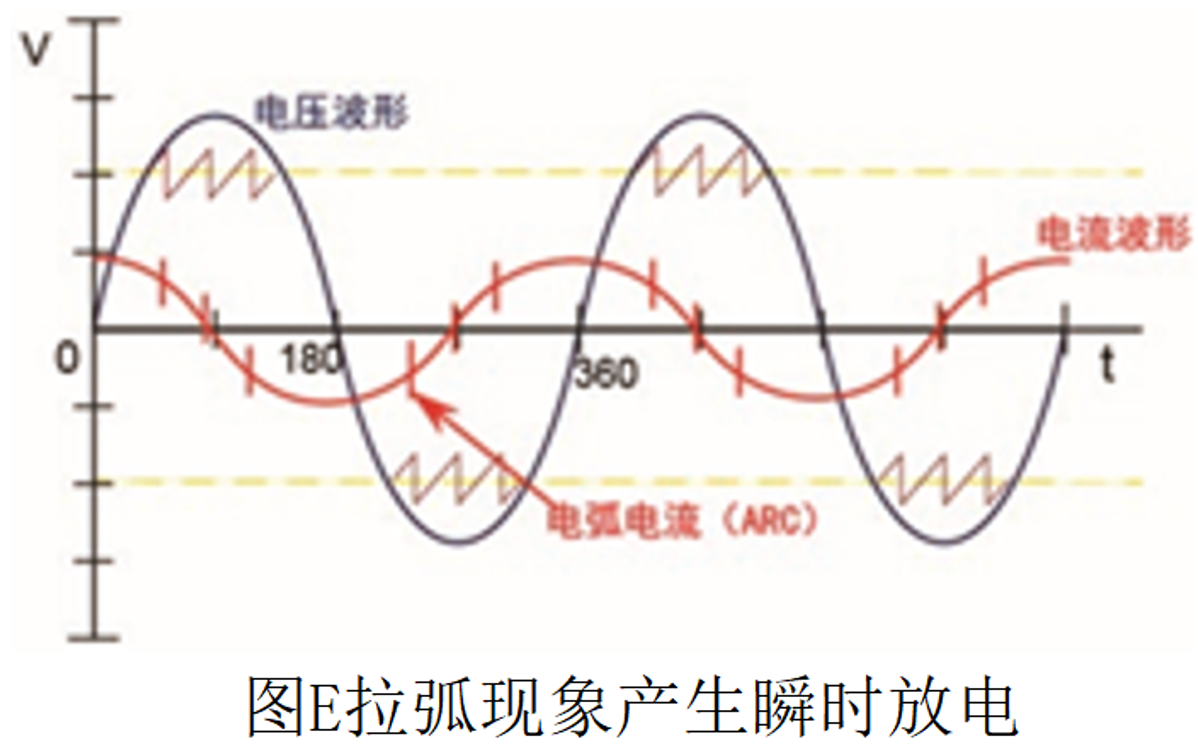

b) the detection of parts under test when the distance between the points is too small, in the parts under test at both ends of the higher voltage applied, the detection of the air at both ends of the space will be ionized, the formation of the phenomenon of ignition, that is, the phenomenon of pulling the arc. Arc phenomenon produces high-frequency transient discharge, in the test process produces a high-frequency current signal as shown in Figure D. Arc Detection (ARC) function is to use high-frequency power measurement to detect the way to determine whether the material insulation performance is bad.

| TH9010 | TH9010A | ||

| Number of units | 8-way independent unit | 4-way independent unit | |

| Pressure resistance test | |||

| output voltage | AC | 0.10kV - 5.00kV ± 2% | |

| DC | 0.10kV - 6.00kV ± 2% | ||

| Current Test Range | AC | 0mA - 10.00mA ± (2% of reading + 5 words) | |

| DC | 0uA - 5.00mA ± (2% of reading + 5 words) | ||

| Rapid Discharge Function | Automatic discharge at the end of the test (DCW) | ||

| Insulation resistance test | |||

| output voltage | 0.10kV - 1 .00kV ± 2% | ||

| Resistance Test Range | 0.1MΩ - 10.0GΩ | ||

| Resistance Test Accuracy | 0.10MΩ - 999MΩ ±10%

1.00GΩ - 10.0GΩ ±20% 0.10MΩ-999MΩ ±10% 1.00GΩ-10.0GΩ ±20% 0.10MΩ-999MΩ ±10% 1.00GΩ-10.0GΩ ±20% 0.10MΩ-999MΩ ±10% 1.00GΩ-10.0GΩ ±20%1 00G 0 1 0.OG 0 ± 20 percent |

||

| Discharge function | Automatic discharge at the end of the test | ||

| arc detection | |||

| Measurement range | Corresponding current | 1 mA -20 mA | |

| General parameters | |||

| Voltage Rise Time | 0.1s - 999.9s | ||

| Test Time Setting (AC/DC) | 0.2s - 999.9s | ||

| Voltage drop time | 0.1s - 999.9s | ||

| Waiting time ( )R) | 0.2s - 999.9s | ||

| time accuracy | ± (1% + 0.1 s) | ||

| memory (unit) | Storage of 100 test files with up to 20 test steps per file | ||

| connector | |||

| standard equipment | HANDLER, RS232, USB DRV, USB HOST | ||

■ 4×4 expansion to expand TH9010A to 4 channels per unit

■ TH9010A supports up to four four-channel scanners.

Expandable up to 64 channels in one instrument

■ Four-channel scanner supports contact checking function

■ Automated test systems

▪ Household appliances

■ Transformers, motors

■ Electrical equipment

▪ Lighting industry

▪ New energy vehicles

■ Electronic components

▪ Medical equipment

| standard equipment | |||||

| Accessory Name | model number | ||||

| DB-25 scanning control cable (hole to pin/1.5m) | TH26072 | ||||

| High voltage test cable (without clamp) | TH90013 | ||||

| High and low voltage connection cables | TH90014 | ||||

| High voltage test cable (with clamp) | TH90017 | ||||

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.