63200A series high power DC electronic loads are mainly used for testing products such as server power supply, A/D power supply, power electronic components, automotive batteries, automotive DC charging piles and some power electronic components. High power, parallel function, synchronized dynamic exclusive ability, more instantaneous three times the rated power pulling capacity, suitable for applications in automotive batteries and fuel cells and other high power to be tested for testing.

The 63200A series is available in three voltage ranges, 60V, 150V, 600V and 1200V, with power ranging from 2kW to 24kW, and a maximum current of 2000A for a single unit, and a maximum power of 240kW when connected in parallel. high power electronic loads can be used to test the charging piles of automobiles and the discharging of automotive batteries.

All models are equipped with User Defined Waveform (UDW) and external signal control functions to simulate real current waveforms; master/slave control capability allows parallel use of the same voltage specifications of the 63200A series electronic loads and synchronized dynamics: automatic frequency dynamic sweep (i.e., loads at different frequencies are simulated) to satisfy the needs of power supply testing. In addition, a 255-group storage function is provided, and the user's stored settings can be called up at any time. In automated testing, this storage and call function reduces test time.

In terms of measurement, the 63200A series also provides accurate measurement functions, instant and accurate voltage and current measurement, with three levels for each model. In addition, short-circuit test is one of the necessary test items for power supply test, and the short-circuit simulation function provided by the 63200A series is an effective solution to the application needs of power supply test and automation test.

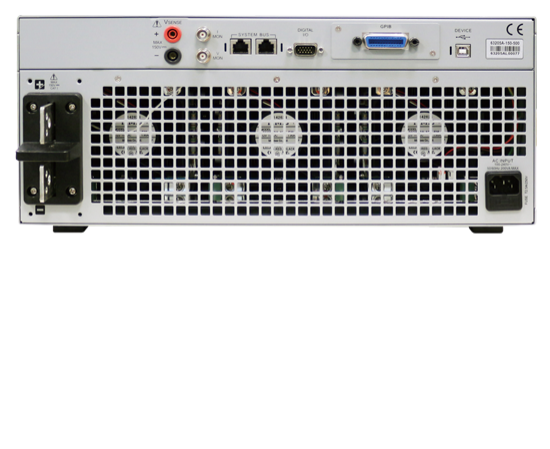

Through the front panel VFD display and knob, it is easy to operate and set up the 63200A series electronic loads, and it can also be remotely controlled wirelessly or wirelessly through Ethernet, USB, GPIB and CAN BUS interfaces.

The built-in PWM fan speed control reduces the noise caused by the fan. The 63200A series also features over-current, over-power, and over-temperature protection, as well as over-voltage and positive/negative reverse alarms, which greatly improve product reliability and are reliable products for engineering testing and automated test system integration.

Scope of Application

Data Center

Server Power

High Voltage UPS

Telecom Power

Solar Panel

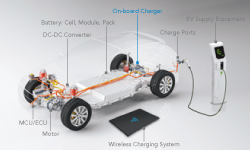

On Board Charger

Battery Pack

Energy Storage System

EV Charger Station

Low Voltage Operating Characteristics

The 63206A-60-1000 model is specially designed to have a low voltage pulling characteristic of 0.6V@1,000A and can still pull current below 0.6V to 0V (refer to the V-I curve for the low voltage operating characteristic). This low-voltage operation characteristic is suitable for testing the V-core of the central processing unit (CPU) and graphics processing unit (GPU) demand voltage in the range of 0.6V~1.5V and current in the range of 400A~800A, as well as fuel cells and other low-voltage and high-current applications.

Note: The 63206A-60-1000 can be used with low inductance/low impedance load line B632008 (optional) to connect to the object to be tested for low voltage testing.

Note: The specification was measured at load terminal of Constant Current Mode operation. (Ambient temperature of 25 ˚C)

High power density and customized shortcut design

Chroma's 63200A series high power programmable electronic loads are equipped with digital signal microprocessors (200MHz) for superior speed and control performance. Ultra-high power density (6kW@4U) saves a lot of space, ultra-high voltage (0.015%+0.015%F.S.) and current (0.04%+0.04%F.S.) measurement accuracy ensures the measurement accuracy, and the whole series of models can be manually operated individually, and remotely operated.

Control, for higher power supplies, can be set to master-slave control to achieve multiple parallel operation, and has the ability to synchronize the pull load to simulate the actual pull load conditions.

With high power density design, the 63200A subverts the concept of high power electronic loads being large in size and inconvenient to move, which saves a lot of space in the laboratory and easily solves the space problem when updating electronic loads for automated test systems. In addition, the 63200A also provides four sets of self-defined shortcut keys, allowing users to more quickly enter the desired mode of operation.

Graphical Options

Clear graphical function options make it easy for users to operate the 63200A series. Basic load functions and advanced functions are graphically displayed, allowing users to select the desired function with knobs and arrow keys. The graphical options are presented in abbreviated form with full name descriptions on the top of the screen, making it easy to get started even without a user's manual.

reversible panel

In the 63200A series, the models with heights of 7U, 10U, and 13U are equipped with the function of reversible face, and the maximum angle of reversal is 70°. The thoughtful design of the reversible panel will bring different experiences and feelings to the users, no matter in the convenience of operation or viewing.

Base load applications

The 63200A series has constant voltage, constant current, constant resistance, and constant power modes of operation to meet a wide range of test requirements. For example, Constant Current and Constant Resistance modes can be used to test a voltage source to verify that the output voltage remains stable under different load conditions. For battery chargers or charging posts, constant voltage mode can change the output voltage of the charger or charging post to ensure that the charger or charging post has the correct charging current at the set output voltage. When the object to be measured is a battery, the electronic load can be changed to simulate the pulling behavior of electronic equipment. Many battery discharge applications and power consumption can be analyzed by simulating the pulling behavior of the electronic load, and the fixed-power mode is one of the choices for simulating the pulling behavior of electronic equipment.

Master/slave parallel control

The 63200A series has an intelligent master/slave control mode, when the load power demand increases, all models with the same voltage specification can be connected in parallel (master/slave control) to achieve the required current and power. When set to master/slave control mode, all the electronic loads set to master/slave control will become a single load. Users only need to program the load current on the master load, and the master load will automatically calculate and distribute the current to the other slave loads, which can greatly simplify the user's operation steps. The entire series can be integrated into a standard 19" wide rack to save space. 600V and 1200V slaves without control panel need to be used with a host computer that has a control panel. 63200A is equipped with USB interface (standard), GPIB, Ethernet, CAN BUS interface (optional), which allows users to perform remote control and other automated test applications through these interfaces. The user can use these interfaces for remote control and other automated test applications.

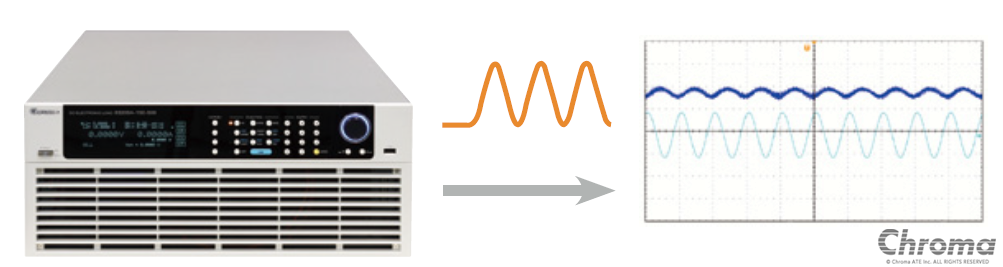

Sine wave dynamic loads

The 63200A series is equipped with a sine wave pull current function that allows the user to set the pull current bias value (I_DC), the pull sine wave (I_AC) and the sine wave frequency value, and the lowest point of this sine wave pull must not be less than zero amperes. This sine wave pull current function can be used for DC internal resistance (DCIR) testing of D/D and server power supplies and fuel cells.

dynamic load

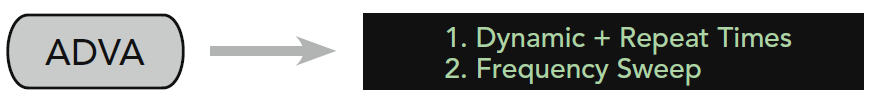

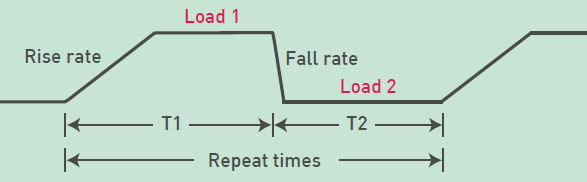

In the fast era, electronic components are designed for high-speed operation, therefore, the performance requirements of power components for transient signals and dynamic response are much higher than in the past. To meet these test applications and requirements, the 63200A series provides high-speed, programmable dynamic loads (dynamic current load CCD and dynamic resistance load CRD), dynamic frequency sweep mode, etc. The following figure shows the programmable parameters: the programmable parameters are as follows. The following figure shows the programmable parameters: set current high/low alignment, T1/T2, climb rate/descent rate and the number of executions. In the 63200A series, the internal monitoring mechanism and circuits minimize current waveform distortion when the load current changes continuously, and the minimum response time for current climb is 10μs for the 150V model, and the dynamic change can be as high as 50kHz.

In addition to the above basic parameters, a new feature allows the user to set the number of repetitions for a certain period of time, ranging from 1 to 65535, which is ideal for testing the instantaneous high-current tolerance of D/D converters and batteries.

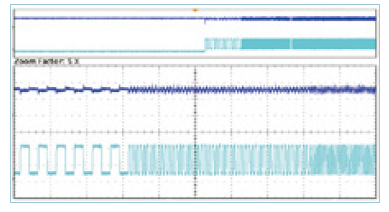

Dynamic frequency scanning control

The 63200A Dynamic Frequency Sweep Mode (shown on the right) linearly varies the frequency of the load current up to 50kHz. This mode measures the maximum/minimum voltage peaks of the object to be measured in the worst case scenario. The sampling rate of this dynamic frequency scanning function is 500kHz. dynamic frequency scanning load mode can simulate a variety of different load conditions, which meets the needs of most users. The 63200A's remote load sensor and control circuitry ensure that waveform distortion is minimized for dynamic load operation at different frequencies.

Constant Impedance Mode (CZ MODE)

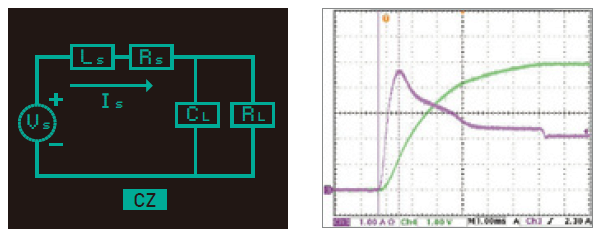

There are many capacitors on the motherboard, in order to avoid charging the capacitors on the motherboard instantly when the server power supply is turned on, and generating an inrush current that triggers the power supply's overcurrent protection mechanism and prevents it from powering on smoothly, the power supply needs to be capacitively loaded for power-on testing, and therefore the 63200A series provides a constant impedance load mode to meet the test requirements.

Constant impedance pull mode is different from constant current and constant power pull mode. Constant impedance mode simulates the actual inductive impedance, impedance, capacitive impedance and load to pull load, so the pull current is closer to the real situation. This waveform shows the simulated voltage and current waveforms of a switching power supply under capacitive load.

Highly accurate measurement

The 63200A series has the industry's most accurate measurement accuracy, with three load positions. Model 63206A-150-600, for example, has three voltage positions, 16V/80V/150V, which meets the testing needs of server power supplies or communication power supplies (12V, 48V, 54V); and three current positions, 60A/300A/600A, which can provide current settings and measurements for different applications with smaller position errors. There are three levels of current 60A/300A/600A, which can provide different applications of current setting and measurement of smaller gear error, and built-in high-precision A/D converter, voltage, current, power measurement specifications were up to voltage 0.015% + 0.015%F.S., current 0.04% + 0.04%F.S., and power 0.1% + 0.1%F.S. of accuracy. Highly accurate measurement is an indispensable function for measuring the efficiency of the object to be measured.

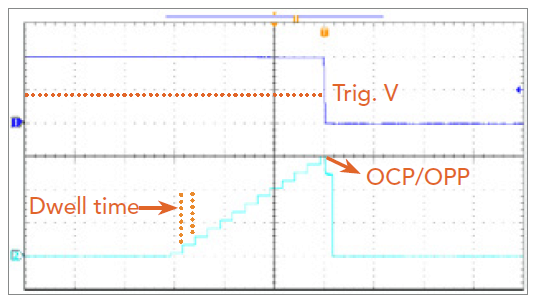

Overcurrent and overpower testing

When designing power supply, in order to ensure the safety of users and reduce the damage rate of power supply, the over-current protection or over-power protection mechanism often needs to be considered and designed. 63200A's over-current and over-power test can provide users to set the step current or step power to carry out the power supply's over-current or over-power protection test, and the electronic load to determine whether the result of this test is Pass or Fail, and the maximum power value (Pmax) during the test can also be automatically captured and displayed on the monitor. The maximum power value (Pmax) during the test can also be automatically captured and displayed on the monitor, which helps users to verify whether the designed overcurrent and overpower mechanism is correct without using an oscilloscope, and reduces a lot of testing time for users.

▲ Overcurrent test

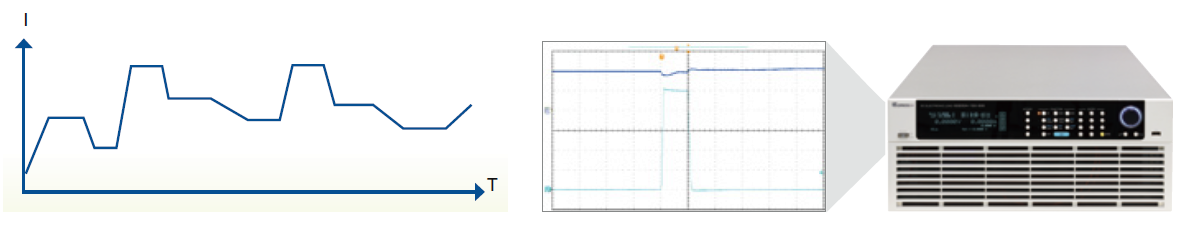

User-defined waveform function (learning mode)

In addition to the general fixed-current, fixed-voltage, fixed-power, fixed-resistance pull-load mode, in the pull-load arbitrary waveforms, the general traditional way is through the computer will be pre-stored waveforms through the DAQ card or simply through the arbitrary waveform generator will be sent to the electronic load for pulling the waveform to achieve the purpose of pulling the load of an arbitrary waveform, as shown in the figure below.

However, the 63200A series provides another more convenient option - user-defined waveforms, which can simulate the real pulling current. The actual current waveform data captured by the oscilloscope or the edited current waveforms can be easily stored in the internal flash memory of the 63200A series through the graphical operation software, and then any waveforms defined by the user can be pulled, which saves the cost of a DAQ card or waveform generator, as shown below. This can save the cost of DAQ card or waveform generator, as shown in the figure below. The 63200A series provides a total of 10 groups of storage space for waveforms, with a maximum of 1.5 million waveform points, which is sufficient to provide the required testing.

In addition, while pulling the actual current, the 63200A series also provides the positive and negative values of the maximum peak voltage that occurs during the pulling process, so that the user does not need to observe the voltage changes through an oscilloscope, which greatly saves the time needed to confirm the voltage peaks with an oscilloscope.

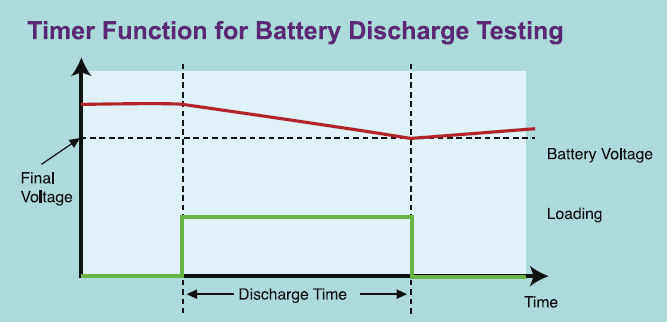

Battery Discharge Test

For battery discharge testing, the 63200A provides users with three discharge modes: constant current, constant resistance, and constant power, and by setting the cut-off voltage and stopping time (1~100,000 seconds), the electronic load can stop pulling the load correctly to ensure that the battery will not be damaged due to over-discharge. In addition, in terms of measurement, it can measure the battery's discharge capacity (WH, AH) and total discharge time. Example: When Load ON is pressed to start pulling a load, the internal timer of the 63200A series will start counting until the battery voltage drops to the set cut-off voltage or Load OFF is pressed to stop pulling the load, then the timer will stop counting. The battery discharge test function can also be used for ultra capacitor discharge time test and other similar applications.

▲ Battery Discharge Test

Programmable Load Timing Function

The 63200A series has 255 built-in programmable load timings that allow users to simulate a variety of real-world load pulling conditions. The following are examples of common programmable timing applications.

- Battery discharge and other applications (notebook computers, electric vehicles, and electric locomotives), simulate a variety of different dynamic pull current waveforms, i.e., provide dynamic current simulation with more than two current levels or one shot pull simulation.

- Mixed-load modulation of server or communication power supply.

digital capture function

Users can record voltage and current transient waveforms through the digital capture function of the 63200A. The digital capture function allows users to operate more conveniently and saves users' time. The following are the specifications for setting parameter values.

- Sampling time: 2 microseconds ~ 40 milliseconds / Resolution: 2 microseconds (set sampling interval)

- Sampling points: 1 ~ 15,000 (set total sampling points)

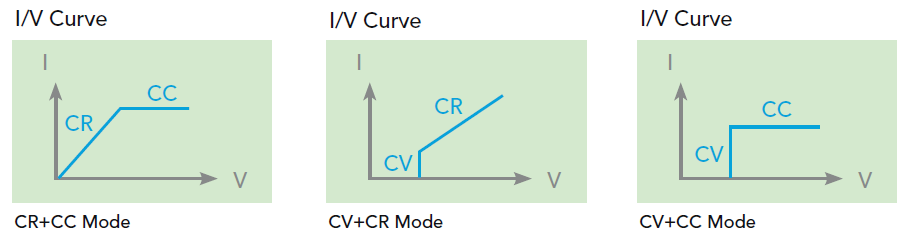

Composite mode of operation

Novel composite operation modes CR+CC, CV+CR, CV+CC modes, etc. CR+CC is suitable for the application of power-on test of power supply; CV+CR can replace the application of Von point setting, and CV+CC can be applied to the discharge test of battery.

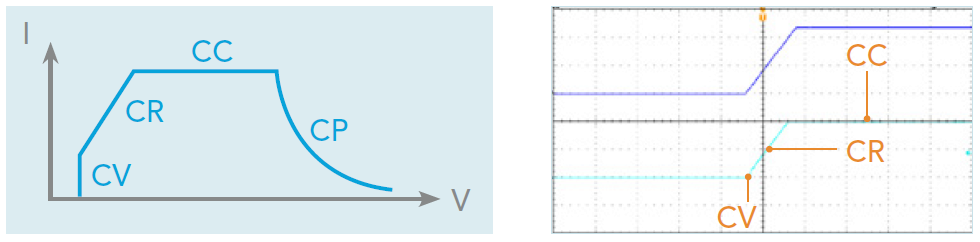

Automatic mode/strong

The auto mode can automatically switch between constant voltage (CV), constant resistance (CR), constant current (CC) mode and constant power (CP) mode under the constraints of the auto mode, which is suitable to be applied to the testing of lithium-ion battery chargers in order to obtain a complete V-I charging curve. In addition, when the protection circuit of the object to be tested is damaged, the automatic switching mechanism of the automatic mode can be used to avoid the damage of the object to be tested.

graphical operating software

In addition to controlling the module load via the front panel, the module can also be controlled via a graphical operating software. The user-friendly graphical operation software interface, which includes the module's operation functions, makes it easy for users to get started and easy to operate. The communication interfaces of 63200A series include GPIB, USB, Ethernet and CAN BUS, which allow users to have more flexible choices when communicating with 63200A series through PC.

63200A DC Electronic Load for High Power Applications

| High Power Application | 150V | 600V | 1,200V | Note Load cable not included |

|---|---|---|---|---|

| 48kW | 4,000A | 3,360A | 1,920A | - 63224A-150-2000x2 - 63224A-600-1680x2 - 63224A-1200-960x2 |

| 60kW | 5,200A | 4,200A | 2,400A | - 63224a-150-2000x2 + 63212a-150-1200x1 - 63224a-600-1680x2 + 63212a-600-840x1 - 63224a-1200-960x2 + 63212a-1200-480x1 |

| 120kW | 10,000A | 8,400A | 4,800A | - 63224A-150-2000x5 - 63224A-600-1680x5 - 63224A-1200-960x5 |

| 240kW | 20,000A | 16,800A | 9,600A | - 63224A-150-2000x10 - 63224A-600-1680x10 - 63224A-1200-960x10 |

| 480kW | 40,000A | 33,600A | 19,200A | - 63224A-150-2000x20 - 63224A-600-1680x20 - 63224A-1200-960x20 Customized, call for availability |

| model number | relate (a story or information) |

| 63200A Series | High Power Programmable DC Electronic Load |

| 63206A-60-1000 | High Power Programmable DC Electronic Load 60V / 1000A / 6kW |

| 63202A-150-200 | High Power Programmable DC Electronic Load 150V / 200A / 2kW |

| 63203A-150-300 | High Power Programmable DC Electronic Load 150V / 300A / 3kW |

| 63204A-150-400 | High Power Programmable DC Electronic Load 150V / 400A / 4kW |

| 63205A-150-500 | High Power Programmable DC Electronic Load 150V / 500A / 5kW |

| 63206A-150-600 | High Power Programmable DC Electronic Load 150V / 600A / 6kW |

| 63208A-150-800 | High Power Programmable DC Electronic Load 150V / 800A / 8kW |

| 63210A-150-1000 | High Power Programmable DC Electronic Load 150V / 1000A / 10kW |

| 63212A-150-1200 | High Power Programmable DC Electronic Load 150V / 1200A / 12kW |

| 63215A-150-1500 | High Power Programmable DC Electronic Load 150V / 1500A / 15kW |

| 63218A-150-1800 | High Power Programmable DC Electronic Load 150V / 1800A / 18kW |

| 63220A-150-2000 | High Power Programmable DC Electronic Load 150V / 2000A / 20kW |

| 63224A-150-2000 | High Power Programmable DC Electronic Load 150V / 2000A / 24kW |

| 63202A-600-140 | High Power Programmable DC Electronic Load 600V / 140A / 2kW |

| 63203A-600-210 | High Power Programmable DC Electronic Load 600V / 210A / 3kW |

| 63204A-600-280 | High Power Programmable DC Electronic Load 600V / 280A / 4kW |

| 63205A-600-350 | High Power Programmable DC Electronic Load 600V / 350A / 5kW |

| 63206A-600-420 | High Power Programmable DC Electronic Load 600V / 420A / 6kW |

| 63208A-600-560 | High Power Programmable DC Electronic Load 600V / 560A / 8kW |

| 63210A-600-700 | High Power Programmable DC Electronic Load 600V / 700A / 10kW |

| 63212A-600-840 | High Power Programmable DC Electronic Load 600V / 840A / 12kW |

| 63215A-600-1050 | High Power Programmable DC Electronic Load 600V / 1050A / 15kW |

| 63218A-600-1260 | High Power Programmable DC Electronic Load 600V / 1260A / 18kW |

| 63220A-600-1400 | High Power Programmable DC Electronic Load 600V / 1400A / 20kW |

| 63224A-600-1680 | High Power Programmable DC Electronic Load 600V / 1680A / 24kW |

| 63202A-1200-80 | High Power Programmable DC Electronic Load 1200V / 80A / 2kW |

| 63203A-1200-120 | High Power Programmable DC Electronic Load 1200V / 120A / 3kW |

| 63204A-1200-160 | High Power Programmable DC Electronic Load 1200V / 160A / 4kW |

| 63205A-1200-200 | High Power Programmable DC Electronic Load 1200V / 200A / 5kW |

| 63206A-1200-240 | High Power Programmable DC Electronic Load 1200V / 240A / 6kW |

| 63208A-1200-320 | High Power Programmable DC Electronic Load 1200V / 320A / 8kW |

| 63210A-1200-400 | High Power Programmable DC Electronic Load 1200V / 400A / 10kW |

| 63212A-1200-480 | High Power Programmable DC Electronic Load 1200V / 480A / 12kW |

| 63215A-1200-600 | High Power Programmable DC Electronic Load 1200V / 600A / 15kW |

| 63218A-1200-720 | High Power Programmable DC Electronic Load 1200V / 720A / 18kW |

| 63220A-1200-800 | High Power Programmable DC Electronic Load 1200V / 800A / 20kW |

| 63224A-1200-960 | High Power Programmable DC Electronic Load 1200V / 960A / 24kW |

| 63200A series * | High Power Programmable DC Electronic Load 1200V / 960A / 24kW (Contact Chroma office) |

| 63200A series * | High Power Programmable DC Electronic Load 150V / 5200A / 60kW (Contact Chroma office) |

| 63200A series * | High Power Programmable DC Electronic Load 150V / 10000A / 120kW (Contact Chroma office) |

| 63200A series * | High Power Programmable DC Electronic Load 150V / 20000A / 240kW (Contact Chroma office) |

| 63200A series * | High Power Programmable DC Electronic Load 150V / 4000 |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.