Chroma 8020 Adapter/Charger Automated Test System is suitable for testing adapters and chargers on production lines. 8020 can support simultaneous testing of multiple objects to be tested at a time, which greatly enhances the production line's capacity, and with the flexible hardware architecture of the Chroma 8000 system, you can choose from a wide range of hardware, such as AC power supplies, electronic loads, timing/noise analyzers, power meter, etc.

The 8020 is especially tailored to the characteristics of adapters and chargers, and optimizes the standard test items, with good test performance to meet the requirements of mass production, in addition, the software function is simple to operate and easy to use, which meets the needs of the production line.

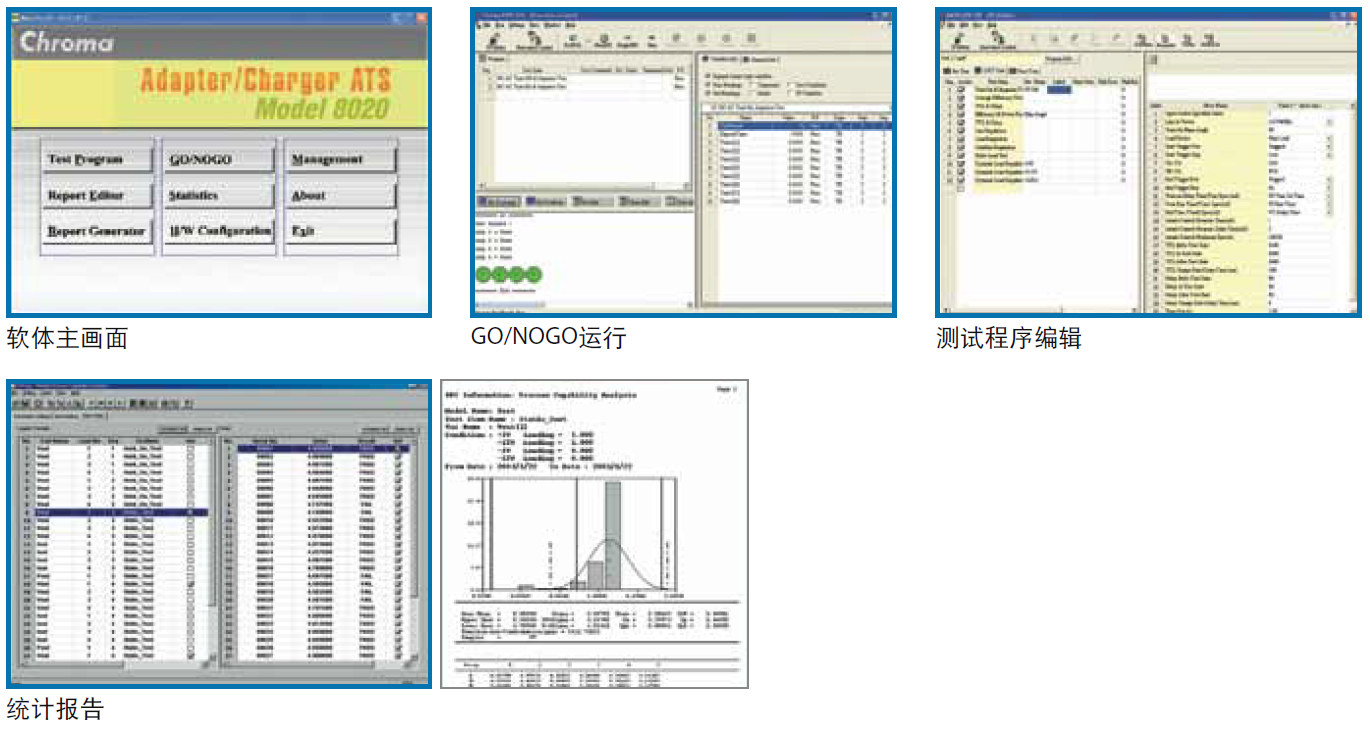

The Chroma 8020 test system has been designed to meet the industry's new test requirements by expanding the hardware and adding new test items such as the Energy Star compliant average efficiency test. In addition, to meet the industry's new testing needs in the future, the Chroma 8020 test system software with report creation, statistical analysis and management functions can be flexibly added to generate various test reports for system management to meet the needs of modern quality assurance and production lines. In addition, this system can also be connected to the manufacturing information system (Shop-Floor System) to control the production process.

The Chroma 8020 automated test system runs on Windows 7/10 or above, providing test engineers with a dedicated power supply test system in an easy-to-learn Windows environment with easy access to Windows resources.

Optimized test items

Chroma 8020 automatic test system is equipped with standard test items optimized for the characteristics of the object to be tested (adapter/charger), users only need to define the test conditions and test specifications on the standard test items to test. The optimized test items cover 7 types of power supply test requirements: Output Performance to detect the general performance of the object to be tested, Input Characteristic to detect the input parameters of the power supply, Regulation Tests to detect the stability of the object to be tested when the input power supply and the load change, and Timing and Transient Tests to detect the stability of the object to be tested when the input power supply and the load change. Stability, Timing and Transient (Timing & Transient) measure the transient state and the time of each event during power-on and power-off, Protection Tests (Protection Tests) trigger the protection circuit of the power supply, Special Tests (Special Tests) and Special Features provide special functions and methods for testing the power supply. Special Tests and Special Features provide special functions and methods for testing power supplies.

Output Characterization Test

|

Input Characterization

|

Stability Test

|

Timing and transient characterization

|

Protective Characterization Test

|

Special tests

|

special function

|

Automated test system software platform

The software platform of Chroma 8020 automatic test system is especially designed for production on-line use, and the whole software function is easy to operate. the software of Chroma 8020 automatic test system runs on Windows 7/10 or above operating environment, which provides the necessary peripheral support for it.

Chroma 8020 automated test system is suitable for modern mass production line, with support for Chroma Sajet Manufacturing Execution System (MES) for the control and management of test stations, personnel, product serial number and test program, as well as the uploading of test data to the central server function, to achieve centralized management of test programs and data collection / report analysis and other applications to help customers complete the goal of intelligent factory. The centralized management of test programs and data collection/report analysis are achieved to assist customers in accomplishing the goal of smart factory, improving product quality and efficiency, reducing production costs, and maximizing corporate benefits. In addition, Chroma can provide customized Shop-Floor control system services to link with existing MES in the customer's factory, and has assisted many world-class manufacturers to complete the MES system integration of real cases.

In addition, in response to the trend of Industry 4.0 fully-automated intelligent production line, Chroma 8020 automatic test system also completes the system hardware and equipment status self-test function, after each product test, it will automatically carry out the status review of the hardware and equipment, when there is an abnormality in the test equipment or the system, the Chroma 8020 system can be integrated with the digital I/O device, the output of the digital signal to notify the management center. The Chroma 8020 system can integrate digital I/O devices to output digital signals to notify the management center, and record the "system start test time", "system end test time", and the message of abnormal error on the local computer, which is convenient for the user to trace the reference and statistics, in order to adjust the equipment maintenance cycle and deployment.

Common mode noise measurement solution for cell phone chargers

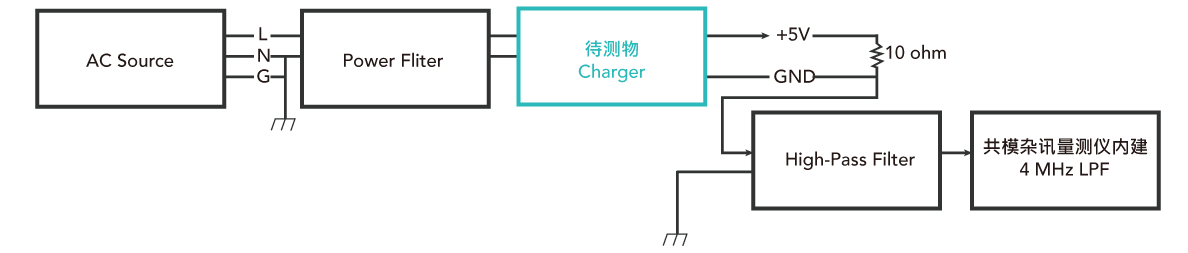

The study found that smart phones use capacitive multi-touch screen, in the charging process from the AC-DC charger generated by the common-mode noise voltage surges in the touch panel, seriously affecting the touch performance, often leading to inaccurate touch reading or cause false touch signals, so cell phone manufacturers to work together to develop the IEC62684 standard, standardize the noise spectrum of the battery charger specifications.

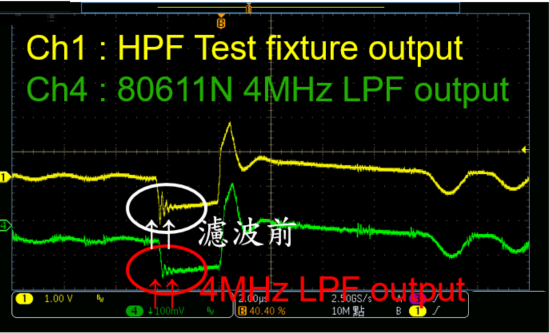

The IEC62684 MoU standard defines the components of common mode noise, specification limits and recommended measurement settings for mobile device chargers. The Chroma 80611 timing/noise analyzer has a built-in 4Mhz low-pass filter that filters out <250ns high-frequency noise and meets the requirement of ignoring <250ns high-frequency noise. The Chroma 80611 timing/noise analyzer has a built-in 4Mhz low-pass filter that filters out <250ns high-frequency noise, which meets the requirement of negligible <250ns high-frequency noises.

Charger Common Mode Noise Basic Test Architecture

| installations | model number | appliance |

|---|---|---|

| input source | Chroma 6500/61600/61500 AC Source | The IEC62684 specification requires a test input voltage of 253Vac/50Hz. |

| High-pass filter | Chroma Design | Filters out 50Hz fundamental ripple components without causing high-frequency noise attenuation distortion. |

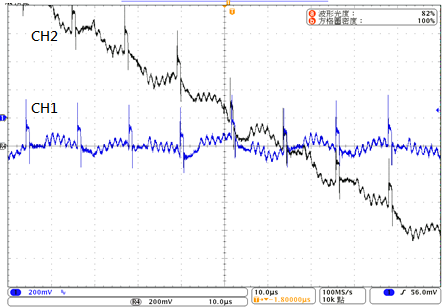

▲ The above waveform CH2 contains 50Hz fundamental frequency ripple components, and CH1 is filtered by HPF without causing high-frequency noise attenuation or distortion. |

||

| common-mode noise meter | Chroma 80611 Timing/Noise Analyzer | Built-in 4MHz LPF filters out <250ns high frequency noise, compliant with IEC62684 specification |

|

||

Comparison with Oscilloscope Measurement

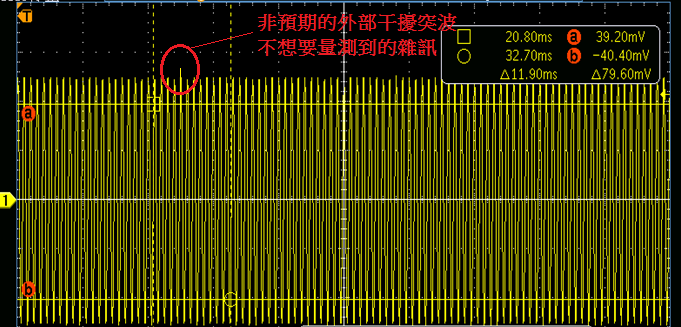

The Chroma 80611 timing/noise analyzer uses analog circuit measurement for sensitive common-mode noise measurement, which can effectively eliminate unstable, discontinuous, and other unanticipated interference bursts, and measure common-mode noise stably and correctly; in addition, the Chroma 80611's differential-mode measurement architecture is different from the oscilloscope's common ground architecture, which can avoid the problem of mutual influence of noise characteristics caused by outputs of the object to be measured during multi-UUT testing. In addition, Chroma 80611's differential mode measurement architecture is different from the oscilloscope's common ground architecture, which avoids the problem of the output of the object to be measured being affected by the common ground during multi-UUT testing.

The oscilloscope is digitizing, and will measure all max peaks on the screen or within the cursor, including discontinuous/unstable noise, and unwanted external interference noise that is not generated by the characteristics of the object to be measured.

| Functional specifications | Chroma 80611 | oscillograph |

|---|---|---|

| Resolution | 400mV/15bit 2V/14bit |

8bit Memory length parameterization affects measurement accuracy and test time. |

| Test speed for multiple test objects at a time | Simultaneous reading of all channel measurements | Only one channel can be used for each measurement, and the measurement values can be read one by one. |

| Number of channels (units) | Chroma 80611: 10CH Chroma 80614: 4CH |

General oscilloscopes (4CH) do not have an external trig port, so when measuring timing, it is necessary to sacrifice a channel to connect to the AC source transition signal. |

| measurement infrastructure | Differential mode measurement: Multi-UUTs can avoid mutual coupling and interference of the noise characteristics of the object to be measured when testing at the same time. | Common-mode measurement: the outputs of the objects to be measured share a common ground, which may cause the output characteristics to affect each other. |

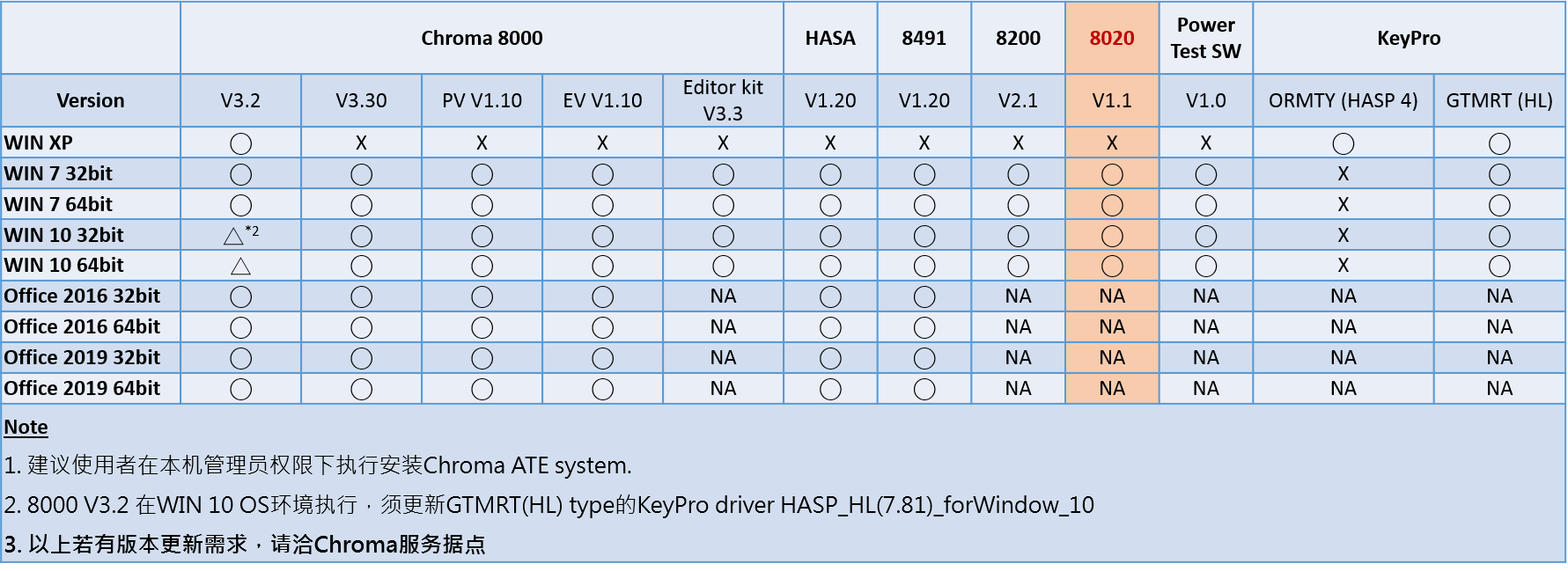

Power supply automatic test system software version and Windows version comparison table

| model number | relate (a story or information) |

| 8020 | Automatic Test System for Adapters/Chargers |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.