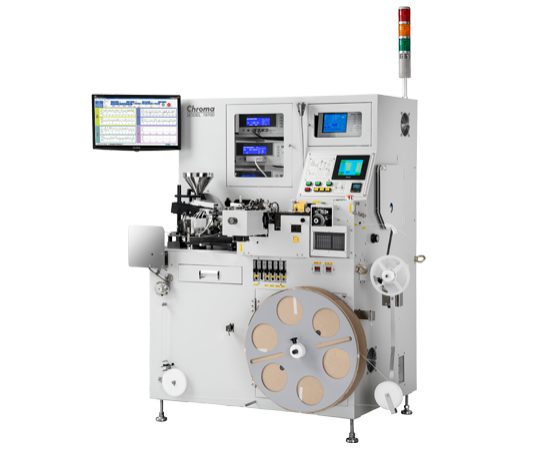

Chroma 1870D series (1870D/1870D-12) is an automated test and production equipment designed for chip type inductors. It includes all the test functions required for chip inductors and has tape and reel packaging automation machinery at the end of the process to automate the manufacturing line.

The standard test functions of Chroma 1870D/1870D-12 include inductance (Ls)/quality factor (Q) measurement, winding resistance (RDC) measurement, polarity test, and optional interlayer short circuit test (IWT), insulation resistance (IR) test, and overlap current (BIAS Current) test, which include standard test items for chip inductance. Includes standard chip inductor specifications and quality related test items.

In response to today's electronic products, miniature inductors are being used in large quantities, and the relative inductors need to be produced in large quantities. The Chroma 1870D/1870D-12 has a maximum production efficiency of 1,200ppm, which is able to satisfy the large number of demands. In addition to testing, the 1870D/1870D-12 is also equipped with an automatic packaging machine, which can automatically package the products on packaging tape and reel to meet the required style for SMD production.

The feeding module of Chroma 1870D/1870D-12 adopts disc vibrating feeder, which can transport thin products at high speed. The vibratory disc feeder uses a track design, fiber optic detection and air blowing holes to determine the direction of feeding, which is faster and less space consuming than the previous linear reciprocating mechanical feeder.

Traditional reciprocating or turret type mechanical structure in the test of load transfer, is designed to suction nozzle adsorption of the product for transfer, often due to the impact of inertia during the transfer of the product fall, or due to inaccurate positioning and can not be tested. 1870D/1870D-12 Chroma test area to guide the disc structure design, the overall closed structure, in the high-speed transfer of products will not have to be missed when the doubt. The Chroma 1870D/1870D-12 test area is designed with a guide disk structure, which is a closed structure and does not cause any product missing during high-speed transfer.

Chroma specializes in electronic test technology and has designed test fixtures for automated test equipment, the test stand of Chroma 1870D /1870D-12 test station is designed for 4-wire measurement, which is more accurate and stable than general automated test equipment. The connection between the test stand and the product is of chip design, which is easier to contact and has a longer life than probes, and the chip design is more stable and easier to maintain than probes.

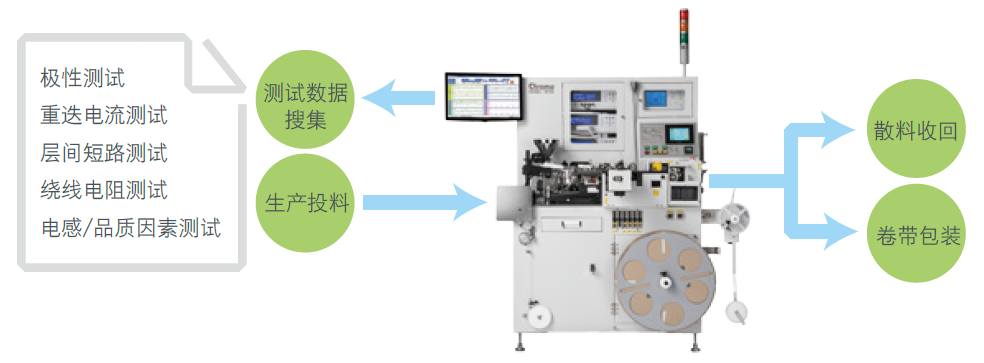

Chroma 1870D/1870D-12 is equipped with specialized software to monitor the test status in real time during the production process and to collect and store the test data of each product. The real-time monitoring function helps the production unit to reduce the production risk during production and minimize the unnecessary production hours. The data collection function facilitates R&D and QA units to do product analysis or quality control, and helps to improve production quality through the software.

Product Applications

R&D, QA batch validation

Chroma 1870D/1870D-12 system provides flexible options to match the test stations according to different units or needs. 12 system provides flexible options to match the test stations according to different units or needs.

Full-featured electrical characterization of production lines

Compared to the R&D side, all electrical characteristic tests are incorporated into the production line, including polarity test, interlayer short-circuit test (or selective overlap current test), winding resistance test, and inductance/quality factor test.

Quick test of nominal value of production line

For production lines that only test nominal values to meet the needs of rapid production, the test program is adjusted to winding resistance testing and inductance/quality factor testing.

System space reservation with labeling and labeling optical inspection

Some of the power inductors need to be labeled on the top to identify the polarity direction or style of the inductor, Chroma 1870D/1870D-12 can be integrated with existing labeling system and optical inspection system.

| model number | relate (a story or information) |

| 1870D Series | Inductive Test Packaging Machine |

| 1870D | Inductive Test Packaging Machine |

| 1870D-12 | Inductive Test Packaging Machine |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.