17020/17040 battery simulator with battery charger/discharger and battery simulator two functions, can be used to test the battery pack and test and battery pack connected to the relevant parts, through the 17020/17040 battery simulator function, to confirm whether the system function is normal, and also can program control the different battery power state (SOC status), and can download different battery curve, test products Charging and discharging status can be downloaded from different battery curves to test the product and the battery with the test evaluation in advance, which can be applied to the automobile start-stop system motor driver, light electric vehicle electronic controller, car charger and other tests.

When users develop a product, they want it to fulfill different applications. Connecting different battery packs to validate the product is a better way. However, when a component is being developed and designed, the supplier's batteries are not yet in place and they are very expensive and difficult to obtain, and it is impossible and costly to obtain each one, so the best way is through the use of a battery simulator.

V2G is the abbreviation of Vehicle-to-grid (Vehicle to Grid), as most of the vehicle 95% time is in the stopping state, the on-board battery can be used as a distributed energy storage unit, this concept describes the future relationship between the electric vehicle and the grid, and then develops the bi-directional on board charger (Bi-direction charger) and the bi-directional DC converter (Bi-direction D/D converter) for automobiles. This concept describes the future relationship between electric vehicles and the power grid, leading to the development of bi-direction on board chargers and bi-direction D/D converters for automobiles. The trend in automotive component development is toward bi-directional design. If such product developers want to validate their products, they cannot use source/load integration. Because the current conversion is interrupted during charging and discharging, the best way to verify the product is to use a battery simulator.

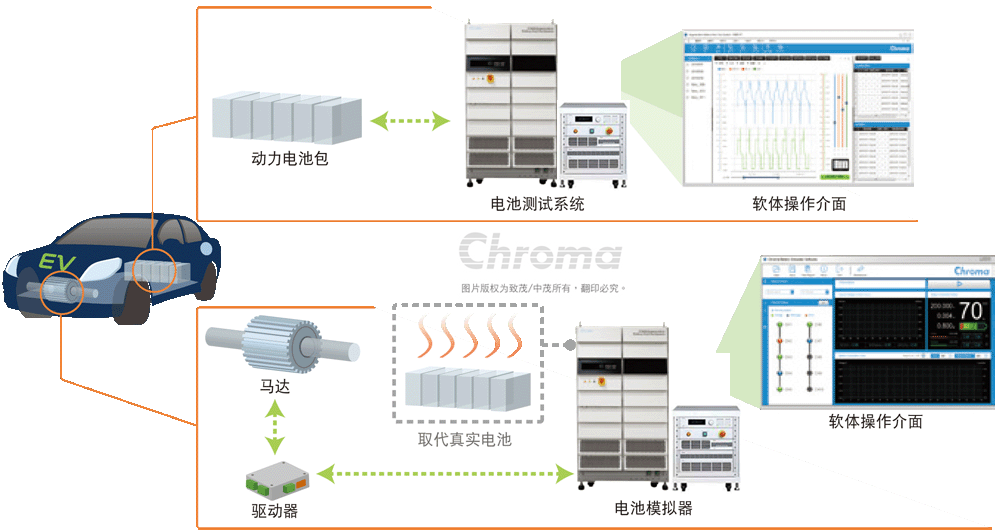

Dual mode application switching

- Charger/Discharger Mode: Power Battery Pack Inspection via Battery Pro Software Interface

- Battery Simulator Mode: Battery Simulator software interface for motor drive/charging post testing.

Battery Emulator Hardware

Chroma 17020/17040 Battery Simulator is designed for energy recovery charge/discharge test system, the operation mode has fixed current/voltage/power discharge with different voltage range 20V, 60V, 100V, 200V, 500V, 1,000V, channels can be connected in parallel to expand the current, the user can adjust the equipment in accordance with the specifications of the battery pack to be simulated. Parallel state, increasing the flexibility of the user on the use of equipment; with a seamless charging and discharging conversion function, can quickly switch between charging and discharging, simulating the actual use of the battery state for two-way parts testing; optimal use of energy recycling, energy recovery design, to save the equipment power and the environment of the air-conditioning costs of the cooling, for example: car charger charging batteries, charging energy can be converted back to the utility plant can be directly utilized. Direct utilization.

Please refer to the detailed hardware specifications:

Energy Recovery Battery Module Test System Model 17020

Energy Recovery Battery Module Test System Model 17040

Battery Emulator

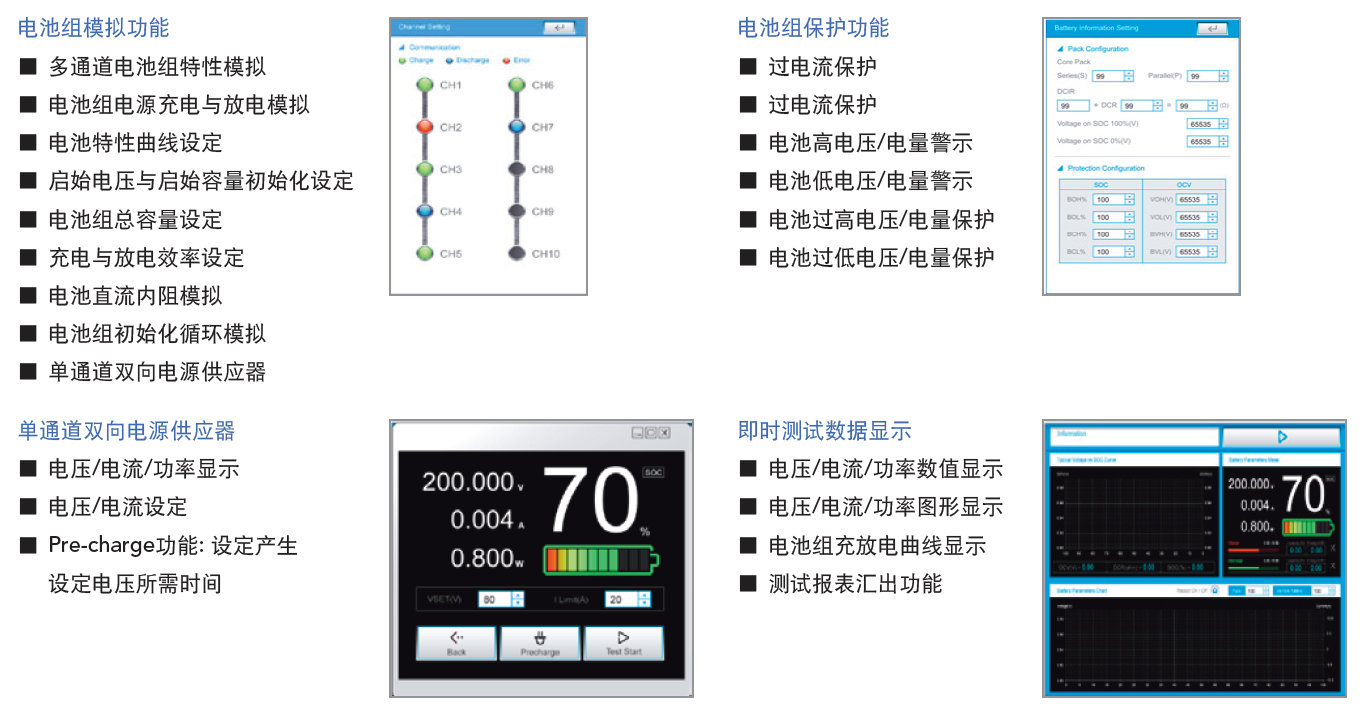

Software for Battery Emulator

Chroma 17020/17040 battery simulator dedicated software, simulating the characteristics of the secondary battery pack, can simulate the voltage output of the battery pack with the change of current state, the voltage output of different SOC states and the change of DC internal resistance at the moment of charging.

Please refer to the detailed soft specifications:

Battery Emulator Soft Panel Model A170202

| model number | relate (a story or information) |

| 17020/17040 | Battery Emulator |

| 17020 | Battery Simulator (Energy Recovery Battery Module Test System + A170202 Battery Simulator Software) |

| 17040 | Battery Simulator (Energy Recovery Battery Module Test System + A170202 Battery Simulator Software) |

| A170202 | Battery Emulator Soft Panel |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.