The Chroma 62000B series of modular DC power supplies offer many unique benefits for burn-in and plating power applications. These features include N+1 redundancy, high power density, hot-plug maintenance, remote ON/OFF control, and programmable remote control monitoring via CAN bus interface.

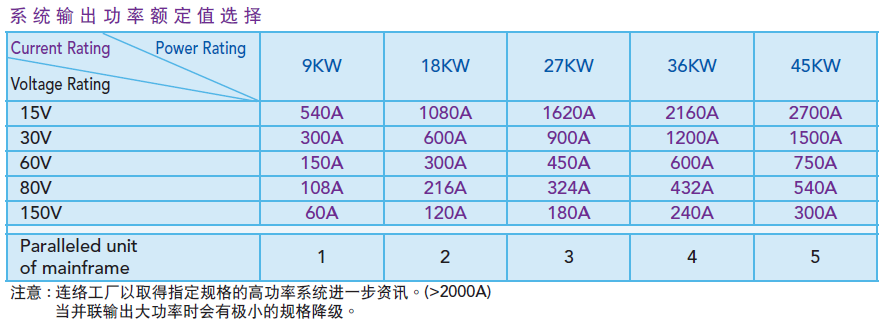

The 62000B series offers five different models of power supply modules with voltages ranging from 1V to 150V and currents ranging from 10A to 90A. In addition, there are two types of module enclosures that can accommodate three and six power supply modules in parallel operation to achieve 4.5KW and 9KW output power. In order to meet the user's high power requirements, the 62000B can be managed via CAN Bus interface and CSU to parallel up to 14 frames with up to 120KW of power and up to 2000A of DC power supply system.

Combining the above features and specifications, the 62000B series DC power supply system is suitable for use in environments where long periods of time and system interruptions are not permitted, and the system has the following advantages:

- Flexible expansion of system output capacity

- The latest switching power supply design features small size and light weight, easy to transport, install and maintain, easy to replace and does not take up much space.

- With power factor to improve line PF>0.98, can make the power utilization rate is good and there will be no false power and harmonic interference with electricity.

- With N+1 Redundant system, a single module failure does not affect the system to reduce the risk of power supply.

- Modular power management and hot-plugging for easy on-site maintenance solutions and spare parts.

62000B Application Areas

The 62000B modular DC power supply offers high power density at an economical price. When the output is operated in constant current mode, its low current ripple characteristics meet the needs of plating power supply or battery charging applications. In addition, when operated in constant voltage output mode, this modular DC power supply can be used for aging burn-in applications such as LCD panels, DC-DC converters, automotive inverters, notebook computers, and many other types of electronic devices and equipment.

The 62000B series power supplies are suitable for industrial applications as follows.

- DC converter/inverter/fan products Burn in

- Current withstand test for fuse/switch/wire/connector, etc.

- Electroplating (copper foil & SMD parts) and electrolytic power supply applications

- Semiconductor Component Burner Power Supplies

- Water electrolysis treatment power supply

- Air motor power supply maintenance power supply

- Graphite heater power supply

- High Concentration Solar Panel Avalanche Power Supply

- Analog Battery Power Supply and Battery Charge Formation Equipment Applications

|

|

|---|---|

| Customer application 1: 21,600A current withstand test for switching assemblies | Customer Application 2: Battery Cell Charging into System Power Supply |

Power Factor Correction Circuit (PFC)

Power Factor Correction (PFC) circuitry has been incorporated into the 62000B to provide input power factor of 0.98 or greater to comply with IEC 61000-3-2. This power factor correction circuitry not only reduces input current, but also maintains operating efficiency beyond 80%. This PFC circuitry not only reduces input current, but also maintains operating efficiencies in excess of 80%. Optional SoftPanel software allows control and monitoring of the output power system through the CAN interface.

Thermal Insertion Operation Maintenance

|

With N+1 redundancy and hot-plugging, the 62000B series of modular DC power supplies can be used for 24-hour operation in applications such as SMD plating lines, product life aging tests, etc., such as DC/DC converters for IT products and LCD backlight inverters.

For continuous operational applications, the modular hot-plug design allows engineers to replace failed modules on the spot without shutting down the entire system. |

High Power DC Power Supply Applications

The 62000B modular DC power supply provides parallel high power outputs up to 120kW, with a maximum current via the CSU (Control & Supervisory System Unit) of 2000 A. Each chassis is designed to match a maximum power of 9kW and includes an equalization output to ensure system stability. In addition, to facilitate control of the uniform high power system, the CSU provides setup and display outputs and communicates via standard CAN Bus protocols.

A620007 CSU Key Features

|

▲Customized High Power Supply Service |

Control of parallel connection

- Mode A: Users can do analog input/output control, remote digital control (CAN/Ethernet) and front panel manual control through CSU.

- Mode B: The user can connect the computer control through the remote control interface (CAN).

Note: ChipMOS can provide Softpanel (application software) for customer's application. - Mode C: Users can control ON/OFF (dry contact) this parallel operation output through remote control.

Note 1: The user cannot adjust the output voltage value in real time when the parallel output is ON.

Note 2: Parallel output voltage values are fixed factory values.

Note 3: If the user wants to adjust the output voltage value, please disengage the parallel connection for stand-alone operation.

Note 4: Output ON/OFF key control voltage to reach the set value time delay takes about 10 seconds.

| model number | relate (a story or information) |

| 62000B Series | Modular DC Power Supplies |

| 62000B-3-1 | Three power module bezels |

| 62000B-6-1 | Six power module bezels |

| 62015B-15-90 | DC Power Supply Module 15V/90A/1350W |

| 62015B-30-50 | DC Power Supply Module 30V/50A/1500W |

| 62015B-60-25 | DC Power Supply Module 60V/25A/1500W |

| 62015B-80-18 | DC Power Supply Module 80V/18A/1440W |

| 62015B-150-10 | DC Power Supply Module 150V/10A/1500W |

| A620007 | Control & Supervisory System Unit (CSU) |

| A620010 | Special 19' frame header for power supply module outer frame |

| A620011 | Ethernet interface card for CSU |

| A620017 | 62000B Series PC Graphical Operation Application Programs |

| A620019 | Module bezel and external box with USB digital control interface for CSUs |

| A620020 | Module bezel and external box for GPIB digital control interface for CSUs |

| A620021 | External box for analog input/output control (APG) and monitoring interface for module bezel |

| A620022 | Module bezel and external box for RS-485 digital control interface for CSUs |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.