Model TH2692 Insulation Resistance Tester is an insulation resistance tester with high voltage creepage speed, high accuracy and high stability.

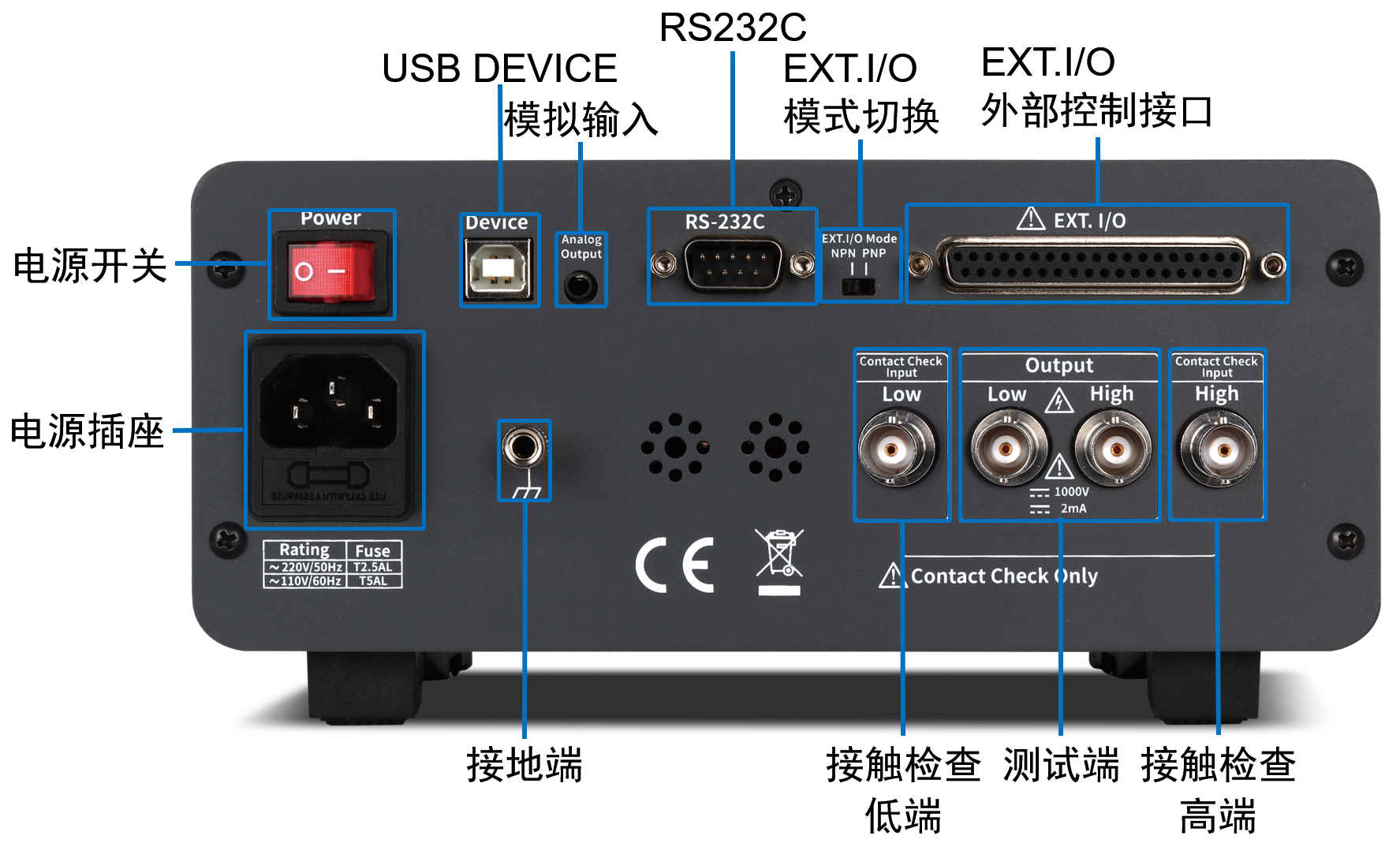

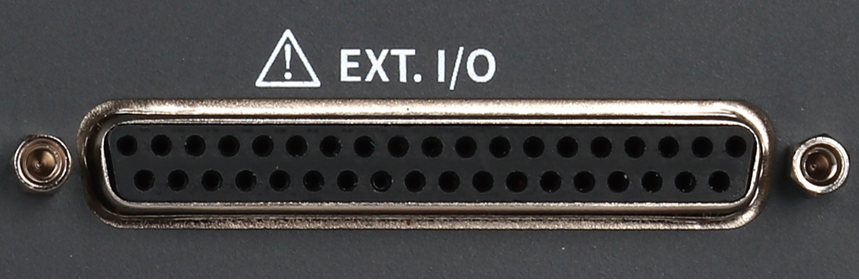

TH2692 has high and low end contact checking function and upper and lower limit sorting function, and is equipped with EXT.I/O interface, RS232C interface and USB DEVICE interface, which can be widely used in automated test of production line.

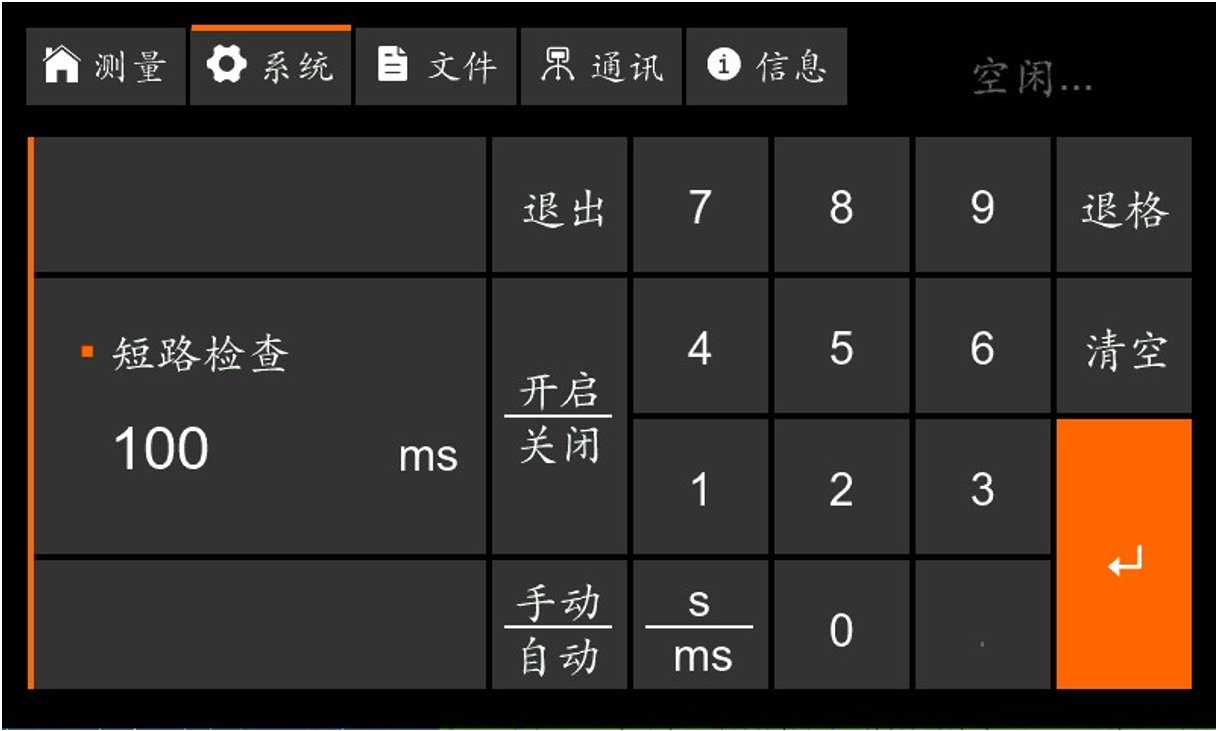

The TH2692 comes with a low-voltage short-circuit detection function that is very suitable for micro-short-circuit testing of battery cells, thus avoiding the risk of the internal micro-short-circuit portion of the battery being burned off due to the application of high voltage, resulting in the defective product being judged as a good product.

Quick Selection:

| Quick Selection | TH2692 |

| Resistance Testing | 10kΩ-100GΩ |

| output voltage | 25V - 1000V |

| Output Current | 0 - 2.4mA |

| Measurement speed | Fast: 50ms Medium: 200ms Slow: 500ms |

Functional Features

- Ultra-compact and fully equipped

TH2692 has a compact size, standard 2U height, front and rear test terminals, and comes standard with RS232C, USB DEVICE, USB HOST, EXT.I/O, Analog and other interfaces, which makes it a perfect fit for both on-shelf testing, test benches and automated production line integration.

- 5Inch capacitive touch screen, friendly interactive interface

TH2692 adopts 5-inch capacitive touch screen, the building block design of the operation interface is simple but comprehensive, measurement parameter setting, measurement parameter readback, limit setting, measurement result judgment, etc. can be displayed in a single page, at a glance.

- The contact check function ensures that the measurement results are correct.

In the insulation resistance test, the judgment is based on the current value or resistance value returned by the measuring circuit to determine whether it is qualified, the higher the insulation resistance represents the better insulation performance.

However, if the test line is broken, or if the surface of the test tooling is oxidized or worn, this can lead to poor contact between the test line and the component under test, in which case the measurement loop will obtain a current value close to zero or an insulation resistance value outside the measurement range of the instrument, and based on the pre-set judging criteria, the result of such readings may be incorrectly interpreted to mean that the component under test is in a good condition, i.e., it is judged to be a good product. However, the truth of the matter is that since the actual test was not carried out effectively, this judgment is inaccurate and therefore constitutes a misjudgment of the state of the component under test.

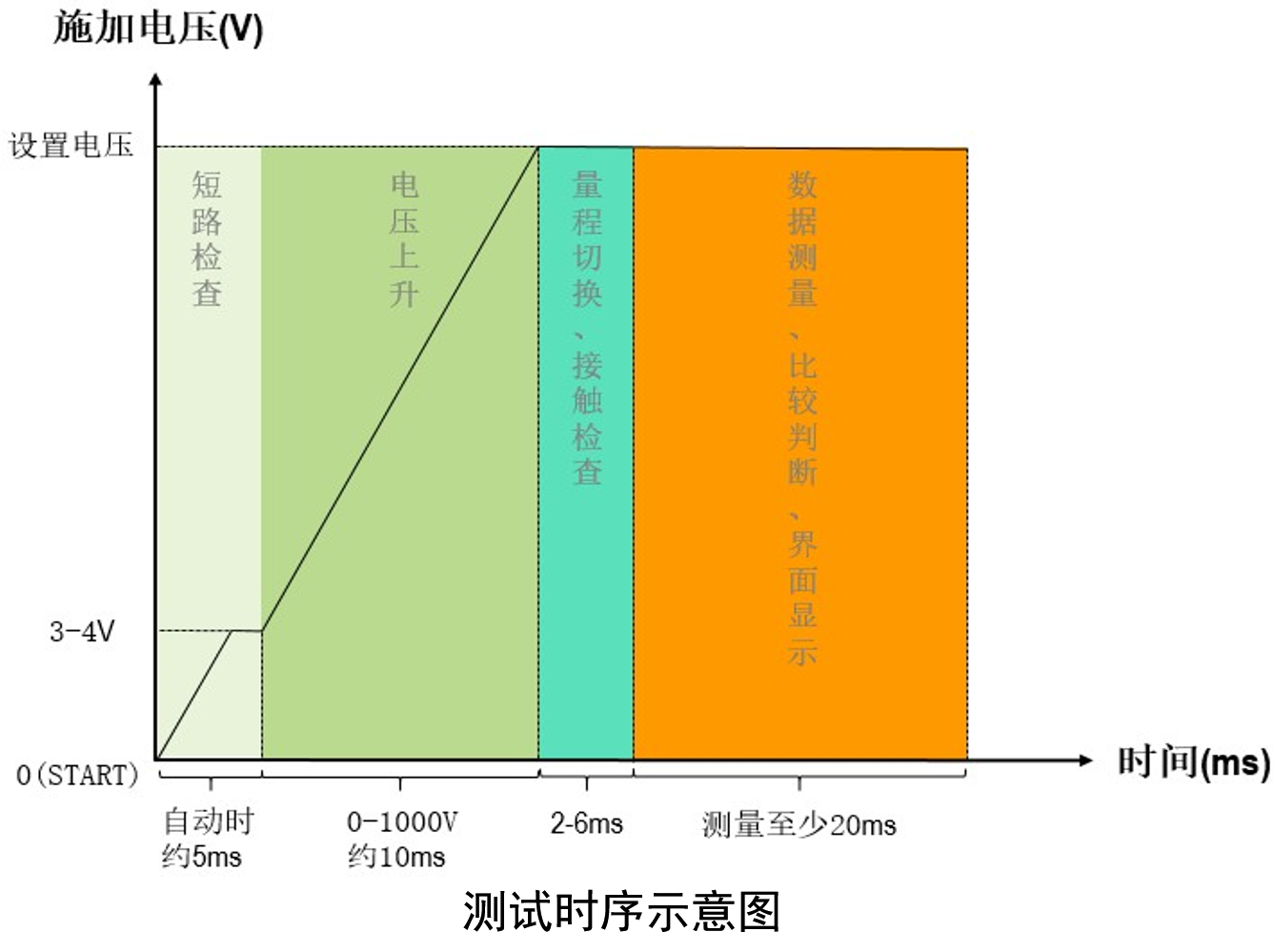

In order to solve this problem, TH2692 is specially designed with a contact checking function, after turning on this function, every time after reading the test voltage, contact checking is carried out to ensure that the sudden interruption of the test circuit in the test process can also be judged in real time, and the main parameter area is displayed in a timely manner to indicate the specific test end of the poor contact.

- Short circuit check (battery micro-short circuit test) function, non-destructive detection of cell micro-short circuit

During the production process of lithium batteries, a tiny localized short-circuit situation, i.e. micro-short-circuit, will be formed inside the battery between the cell and the cell, or inside a single cell. Micro-short circuit situation will not directly burn the battery, but in a relatively short period of time (weeks or months) to reduce the performance of the cell, resulting in the cell or battery pack can not be used at all.

There are several reasons for micro-short circuits

1) Dust or debris: When the core is stacked or rolled, the air environment is not up to standard, resulting in dust or sharp debris adhering to the core diaphragm, piercing the diaphragm and forming a micro-short circuit.

2) Misalignment of the diaphragm of the battery cell: Usually, the edge of the diaphragm shrinks during the production process, resulting in direct contact between the positive and negative poles of the battery cell and causing damage to the battery cell.

3) Poor diaphragm quality: Due to frequent high-current charging and discharging during the use of battery packs, diaphragms of substandard quality are unable to withstand the passage of huge lithium ions in a short period of time, resulting in partial or large-area breakage, and damage to the battery cell after intense heat.

4) Welding process: When ordinary electric welding or spot welding is used, it will lead to micro-welding or bubbles at the welding point of the pole lugs, resulting in the pole lugs falling off easily.

Micro-short circuits are extremely harmful to batteries and are the main cause of self-discharge, mainly in:

(1) The voltage of a single cell in a lithium battery and lithium battery pack drops faster when discharging and rises faster when charging.

2) The battery is completely out of voltage or cannot be charged or discharged.

Therefore, in the battery/cell testing process, the micro-short circuit test is very important. Conventional test methods usually use high voltage or high current test, but this method is very easy to burn the micro-short circuit part directly and lead to the test result is good.

TH2692 adopts a unique design, can effectively circumvent the direct use of high-voltage test leads to burn micro-short circuit parts of the misjudgment results.

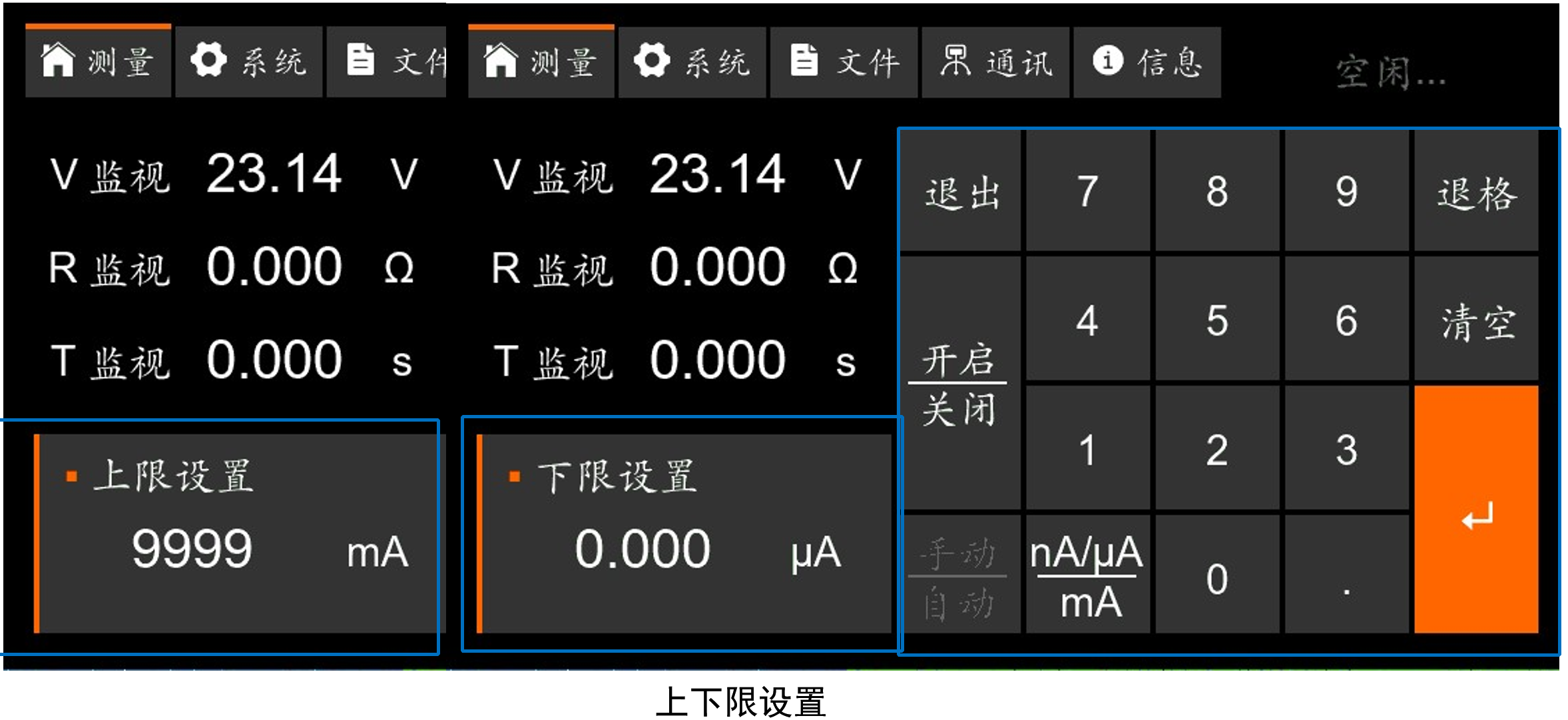

- Primary and secondary parameter comparator, multiple judgment result output methods, suitable for automation system matching.

The instrument can compare and sort current or insulation resistance, the main parameter is insulation resistance mode when the upper and lower limits of the setting range: 0.000 - 1000GΩ, the main parameter is the current mode, the upper and lower limits of the setting range: 0.000 - 1000A, the main and secondary parameters can be directly clicked on the screen main parameter position to quickly switch.

(1) Test results and judgment results are displayed directly on the instrument screen.

Displayed directly on the instrument screen

In addition to displaying the measurement results on the screen, you can also output the results directly by sound with the Comparison Audible function.

2) Data acquisition during testing

The TH2692 can automatically send measured values and judgment results as data to a PC via the RS232C or USB Device interface.

3) Automated testing of interaction signals

For automatic judgment of the automation system, it is possible to receive the trigger signal of the automation line through the EXT.I/O interface and output the measurement result directly through the I/O signal.

The instrument is more thoughtful design of the external interface tester, can be debugged and check the signal status of the external interface signal.

The TH2692 also provides an analog output interface, which can convert the test results into a 0-4V voltage output for the data logger to record.

| Product Model | TH2692 | |||||

| demonstrate | monitor (computer) | 5-inch capacitive touch screen, Chinese and English operation interface | ||||

| Measurement resolution | 3 ¾ | |||||

| Resistance Measurement | Measurement range | 10kΩ - 100GΩ | ||||

| Measurement accuracy | I > 100nA | ±2% readout | ||||

| 10nA < I ≤ 100nA | ±5% readout | |||||

| 1nA < I ≤ 10nA | ±10% readout | |||||

| Display resolution | R < 1GΩ | 3 ¾ position | ||||

| 1GΩ ≤ R < 10GΩ | 2 decimal places | |||||

| R ≥ 10GΩ | 1 decimal place | |||||

| voltage output | Setting range | 25V - 1000V | ||||

| Setting the resolution | 1V | |||||

| Output Accuracy | 1% Setting Voltage ±1V | |||||

| Reading accuracy | 1% Setting Voltage ±1V | |||||

| Display resolution | 25V ≤ set voltage < 40V | 0.01V | ||||

| 40V ≤ set voltage < 400V | 0.1V | |||||

| 400V ≤ Setting voltage ≤ 1000V | 1V | |||||

| Current Measurement | range (of scales or measuring equipment) | 2mA | 200μA | 20μA | 2μA | |

| Test Range | 220μA - 2.4mA | 22μA - 220μA | 2.2μA - 22μA | 0 - 2.2μA | ||

| Display resolution | 3 ¾ position | |||||

| test speed | range (of scales or measuring equipment) | 2mA | 200μA | 20μA | 2μA | |

| speedy | 30-50ms | 80ms | ||||

| medium speed | 200ms | |||||

| slow speed | 500ms | |||||

| Comparator Functions | Resistance upper and lower limits, current upper and lower limits | |||||

| range (of scales or measuring equipment) | Auto, 2mA, 200μA, 20μA, 2μA | |||||

| connector | RS232C, USB DEVICE, USB HOST, EXT.I/O, Analog | |||||

| memory (unit) | 16 test files inside the instrument | |||||

| Working temperature and humidity | 0°C - 40°C, ≤80%RH | |||||

| power supply | AC: 90V-121V (60Hz) or 198V-242V (50Hz),50/60Hz | |||||

| power (output) | 25VA | |||||

| Overall dimensions (mm) | 215(W)×89(H)×154(D) | |||||

| weights | 1.9kg | |||||

- Up to 1000V adjustable test voltage, maximum 2.4mA test current

- 10kΩ-100GΩ Resistance Test Range

- The fastest single measurement is about 50ms

- 5-inch capacitive touch screen, 800 x 480 resolution

- Chinese and English operation interface

- Sorting judgment is possible for both resistance and current.

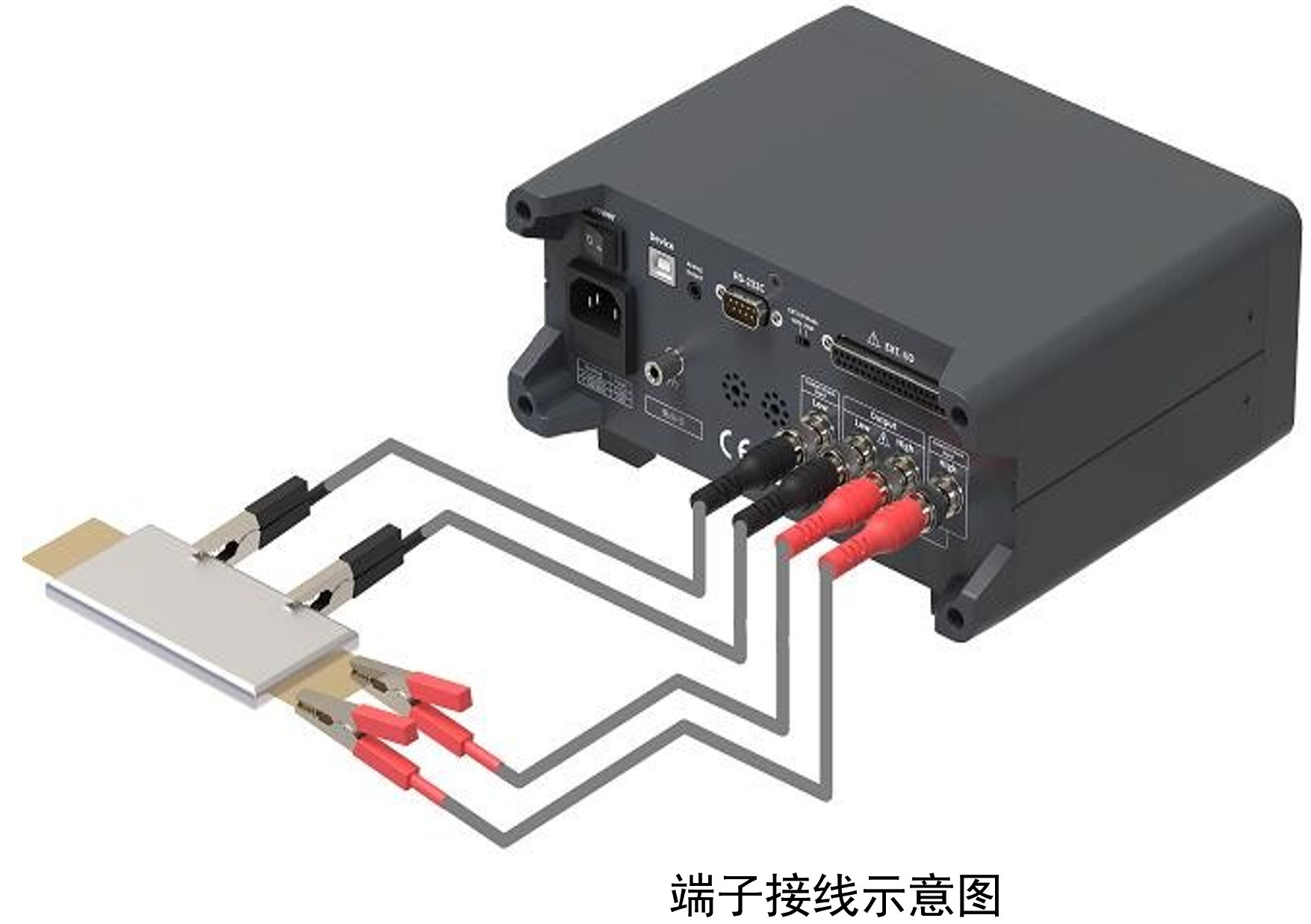

- Four-end contact check function

- Short circuit check function (Battery Micro Short Circuit Test)

- 16 test files saved for quick switching between different test conditions

- Interfaces: USB DEVICE, RS232C, EXT.I/O, Analog Output, USB HOST

n Material characterization tests

Semiconductors, nanomaterials, polymer materials, dielectric materials, electrochemical materials, ferroelectric materials, graphene, ceramics, biomaterials, rubber, thin films, metals, organic materials, etc.

n Leakage current and insulation resistance testing of electronic components

Capacitors, resistors, diodes, transistors, sensors, TFT and CNT types, optoelectronic devices, nanodevices, solar cells, switches, relays, etc.

n New energy batteries

Battery cell micro-short circuit test, insulation resistance test

n I-V Characterization of Semiconductors and Other Devices

| standard equipment | |||||

| Accessory Name | model number | ||||

| DB37 Connection Plug | TH2692-1 | ||||

| optional | |||||

| Accessory Name | model number | ||||

| BNC to φ4 Banana Female | TH2692-2 | ||||

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.