general situation

Meeting the present, preparing for the future

- Ensure that the basic accuracy is *0.03%

- 10MS/s, 1MHz Power Bandwidth, leave it (to sb)Yokogawa isoPRO™Fiber optic isolation technology supports the18classifier for honorific peopleA/Dresolution (of a photo)

- One instrument can analyze simultaneously7phase power, generating in real time more than1000power parameter

- Innovative symmetrical coaxial shunt design ensures accurate current measurement

*Basic power accuracy

Precise, flexible, confident and constantly innovative

- have7User replaceable power units with one slot

- Multiple synchronization enables large multiphase system measurements

- Simultaneous measurement4Speed and torque of motors**

- Simultaneous broadband and harmonic power analysis through configurable advanced filter isolation and measurement of harmonic losses

**Configurable as auxiliary input

Accurate measurements made easy

- 10.1Inch electrostatic capacitive touch screen

- Intuitive and easy menu design

- Modular interconnect design puts safety first

brief

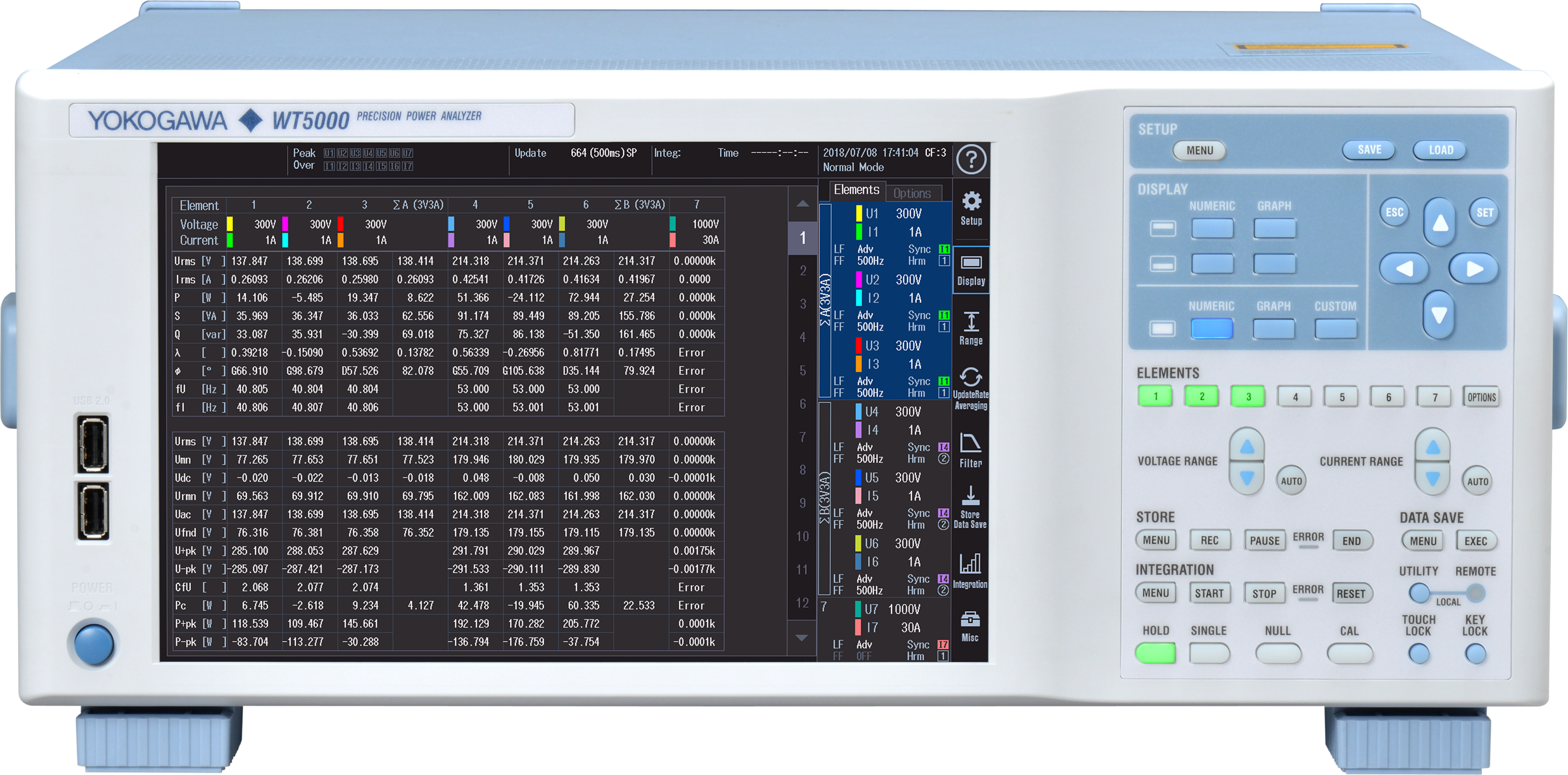

Unrivaled accuracy

WT5000As the world's most accurate precision power analyzer, it ensures a basic accuracy of ±0.03%and in the selected voltage and current ranges of the1%~130%The ranges are all capable of guaranteeing accuracy. WT5000Minimizes the effects of low power factor(apparent power0.02%)It can also accurately measure large phase shifts and frequencies.

- AC power accuracy: readings of0.01%+range0.02%

- DC power accuracy: readings of0.02%+range0.05%

- 10 MS/s 18 bit ADC

Multi-Channel Measurement

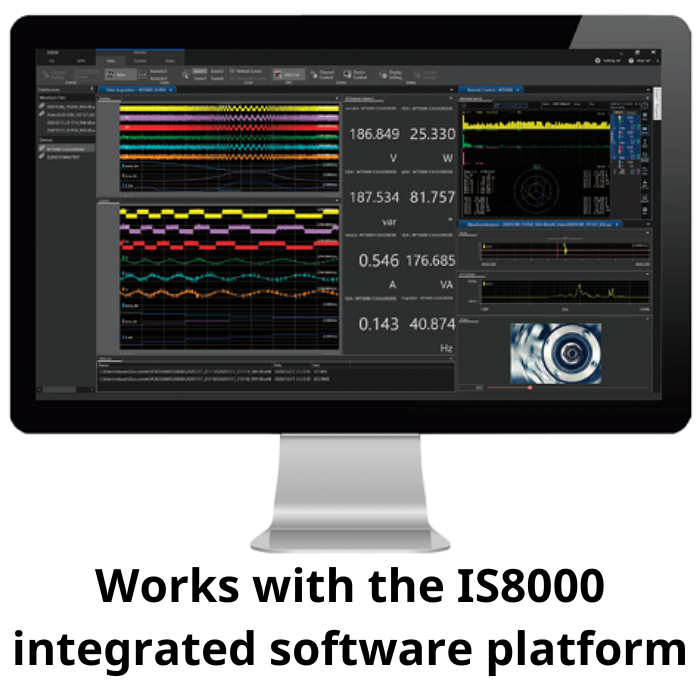

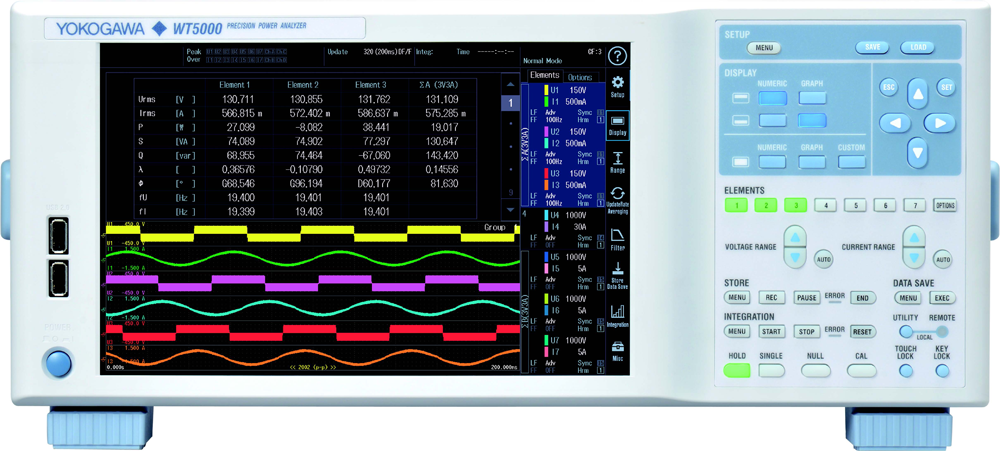

Measurement support for up to7different power phases at sampling rates up to10MS/s(18bit). 10.1inchesWXGAThe display has a high resolution, allowing up to7Split-screen waveform display for groups of up to12Page Measurement parameters are ideal for efficiency testing of inverter-driven motors, renewable energy technologies and traction measurements such as pumps, fans and electric vehicles. Measurement data is also displayed instantly in vector format or as a trend graph.

Current sensor module with DC power supply

Use of the internal DC power supply for AC/DC current sensors simplifies the preparations before measurement and the measurement setup only requires the Using an external DC power supply and additional wiring is no longer required. There are three sensor connection cable lengths available; i.e., 3 m, 5 m, and 10 m. The current sensor can be connected to the AC/DC current sensors by using the internal DC power supply. There are three sensor connection cable lengths available; i.e., 3 m, 5 m, and 10 m. The cable lengths can be used to connect the current sensor to the DC power supply.

*Firmware version 3.01 or later is required.

760903 Current Sensor Element

Example of connection to CT1000A

intuitive operation

WT5000Supporting independent touchscreen and hardware keypad operation, the smooth and intuitive experience makes connecting, configuring and measuring easier than ever. 10.1inchesWXGAThe touch screen maintains excellent immunity to interference even in high noise environments such as motors and inverters.

Additional Touch Operations

The operability of the touch panel has been improved. "Time / div" can be set by pinch / out. Also, you can flick the waveform display contents.

Advanced Filtering

In addition to low-pass frequency filters and line filters, the WT5000Advanced filtering is also available, providing unprecedented control to accurately analyze the most complex waveforms.

- Synchronization Source Filter: Unlike the over-zero synchronization method, the user can select any point of the synchronization source signal.

- Enhanced Frequency Filter: Allows the user to measure both fundamental and switching frequencies without affecting other parameters.

- Digital Parallel Filters: A high-frequency anti-alias filter and two independent line filters work together to ensure that normal and harmonic measurements are accurate and do not cause broadband and harmonic measurements to overlap. The user is able to limit the number of harmonics and eliminate attenuation of low bandwidth measurements.

Advanced Harmonic Analysis

Evaluate and compare inverters, motors or power conditioners up to500times the input and output harmonics. WT5000Allows the user to not only measure harmonics and power at the same time, but also to compare harmonics from two different input sources.

The effects of noise and aliasing are minimized by the adoption of an anti-aliasing function with digital parallel path technology and a line filter that simultaneously analyzes the power of broadband and narrowband components.

Harmonics Regulation Test

Combined with the /G7 option and IEC Harmonic /Flicker measurement software, the WT5000 measured harmonic data can be saved into a PC and tested according to IEC regulations. To support large equipment over 16 A/phase (IEC61000-3-12) the CT200 current sensor model can be used.

- Harmonics: EN61000-3-2, IEC61000-3-2, EN61000-3-12, IEC61000-3-12 and JIS C 61000-3-2

Numeric and Waveform Synchronized Data

The waveform data is streamed without any gaps up to 2 MS/s and is synchronized with the numerical data. Abnormal findings in numerical data can be directly linked and be evaluated in the waveform data. Abnormal findings in numerical data can be directly linked and be evaluated in the waveform data. For example, one can find numeric parameter variations caused by the influence of imposed high-frequency noise. The data can be linked directly and be evaluated in the waveform data.

User-defined triggers and operations

Define and use event triggering and custom arithmetic based on application requirements. Event triggering allows the user to set limits and capture readings within or outside of specific power, current or other parameter limits. Users can also define and use up to20The different expressions for customized arithmetic operations. Data that meets the trigger conditions can be stored, printed, or saved to theUSBStorage devices.

User-defined functions

Follows frequency fluctuations in input signals by auto update mode

This feature can follow fluctuating input frequencies without gaps by changing the data update rate automatically when measuring devices like motors This feature can follow fluctuating input frequencies without gaps by changing the data update rate automatically when measuring devices like motors whose input signal frequency fluctuates with changes in rotation speed. In addition to constant-interval update mode of 10ms-20s, "Auto update mode", which updates data in sync with the cycle of input signal, is now available. new feature is useful for continuous measurement, such as automated testing.

Easy setup menu

Current range, various filters, data update rate, and measurement period can be automatically switched according to the measurement scene.

The measurement scene can be selected from among "50/60Hz," "DC," "PWM," "High Frequency," and "General.

After the automatic setting, the switched items can be checked at a glance and the settings can be easily adjusted.

Wiring with delta conversion useful for motor parameter measurement

When three-phase delta wiring is used, the results of converting to phase voltage using delta-star conversion can be used to measure harmonics, display (When using star connections, it is possible to measure harmonics using the result converted to line voltage using (When using star connections, it is possible to measure harmonics using the result converted to line voltage using star-delta conversion.)

It can calculate the fundamental wave components of phase voltages required for measuring motor parameters (Ld, Lq), and can be used to evaluate synchronous motors.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.