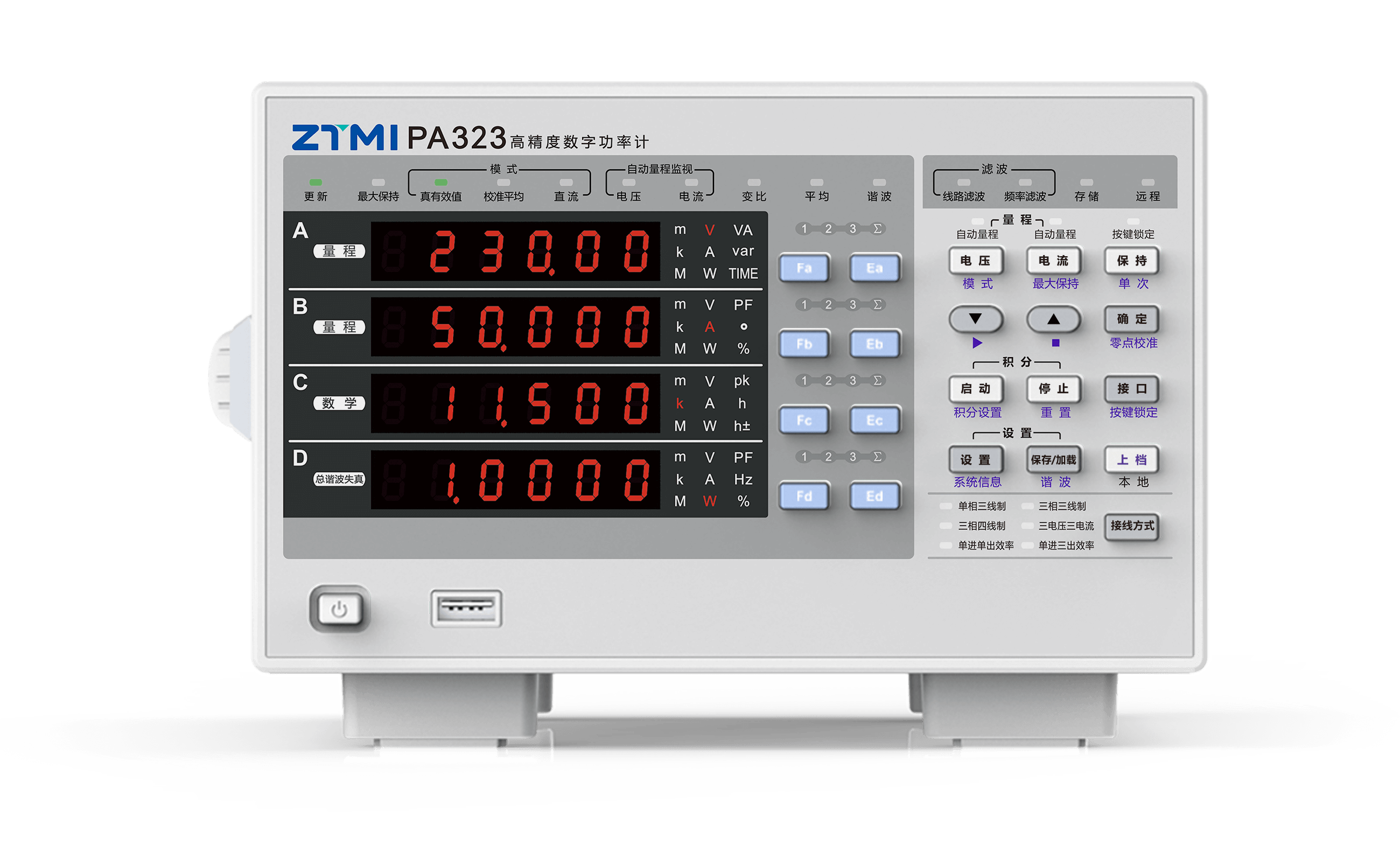

Five core technologies to ensure 0.1% power accuracy

Dual shunt ultra-wide current measurement

The range from 5mA to 20A spanning a large, such as the use of a single shunt, resulting in large temperature drift, low measurement accuracy and other issues. PA300 series digital power meter, the use of dual shunt technology, to maintain the temperature of the shunt resistor steady state change, reduce temperature drift, to achieve from small to large current measurement to ensure that the power of the measurement of the accuracy of 0.1%.

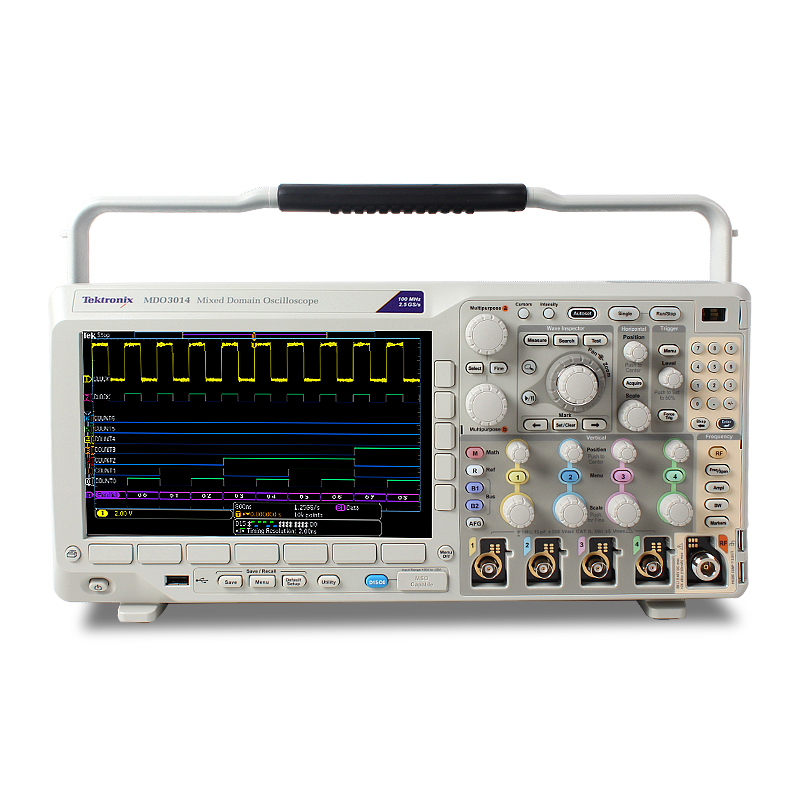

100MHz high speed synchronized sampling

PA300 series digital power meter adopts 100MHz synchronous sampling clock to ensure the sampling phase synchronization of any one channel ADC with an error within 10ns, which reduces the introduction error of U and I angle during measurement and ensures the measurement accuracy of active power and power factor.

High resolution 16-bit ADC

The front-end conditioning circuit effectively solves the problems of temperature drift, noise, etc. Meanwhile, the 16-bit AD is used for high speed rate acquisition of voltage and current analog to ensure the accuracy of the original signal.

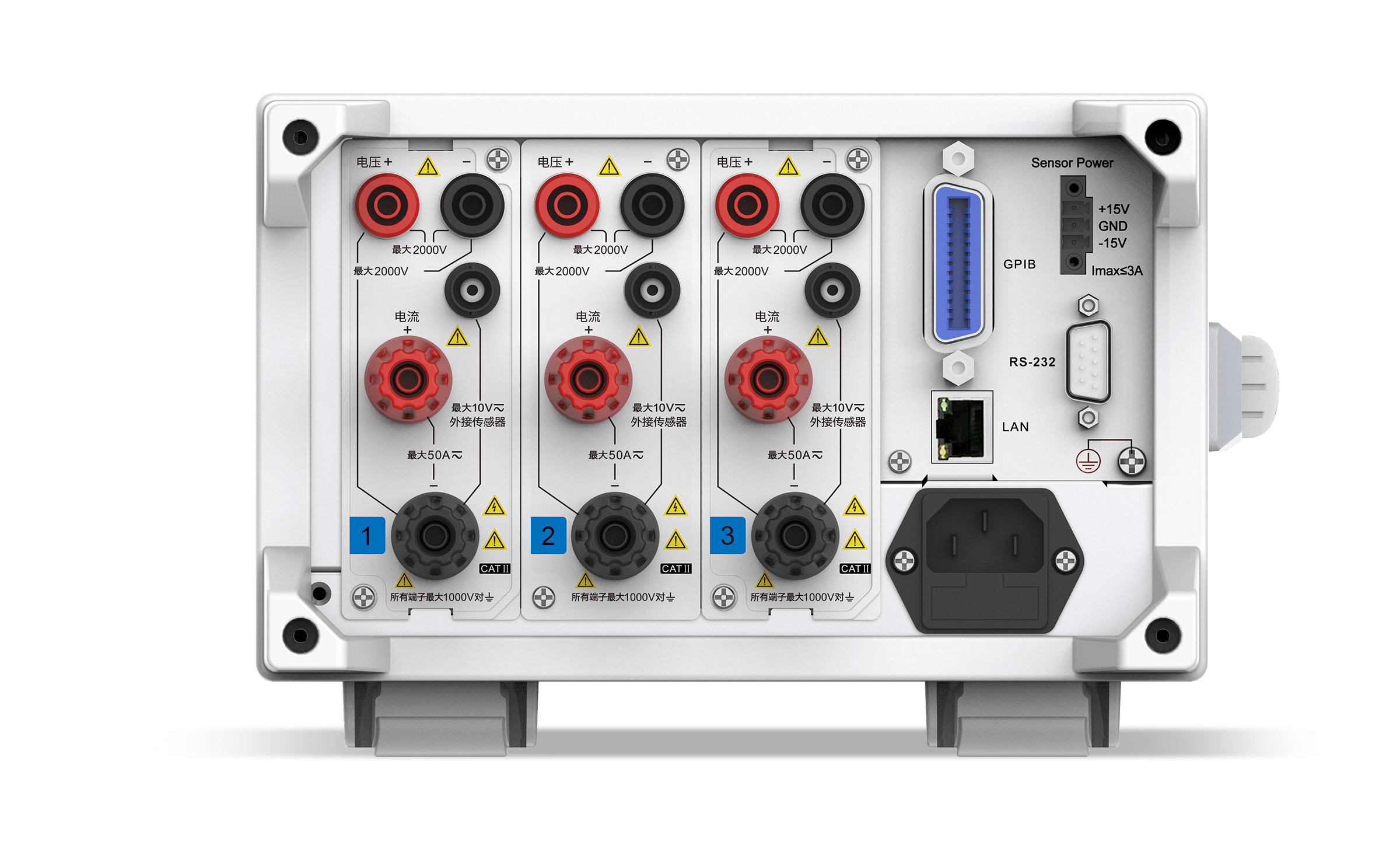

Specialized shielding and isolation technology

Voltage and current channels are using special shielding and isolation technology, isolation between the channels have up to 120dB common mode rejection ratio, to ensure that the inter-channel interference is reduced to a minimum, in the test process can be measured at any location, any point, and the measured system has no relationship with the 0 potential, to ensure that each channel is measured independently.

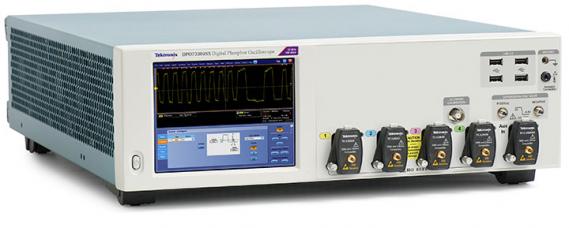

New FPGA+DSP Design Architecture

After the acquisition of large-capacity data need to do fast operation and processing, other brands of power meters are ARM processor or DSP direct operation and processing, but due to the huge data throughput, a single ARM processor or DSP can not do real-time processing; PA300 series power meter adopts the FPGA + DSP design architecture, FPGA co-processing operations with high-speed DSP to realize real-time measurement and processing. The PA300 series power meter adopts the FPGA+DSP design architecture.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.