The Chroma 17020C system is a high-precision device designed specifically for secondary battery module and pack testing. It is suitable for battery module/pack range testing, inbound and outbound product inspection, design validation studies, and production on-line capacity learning (Learning) and testing.

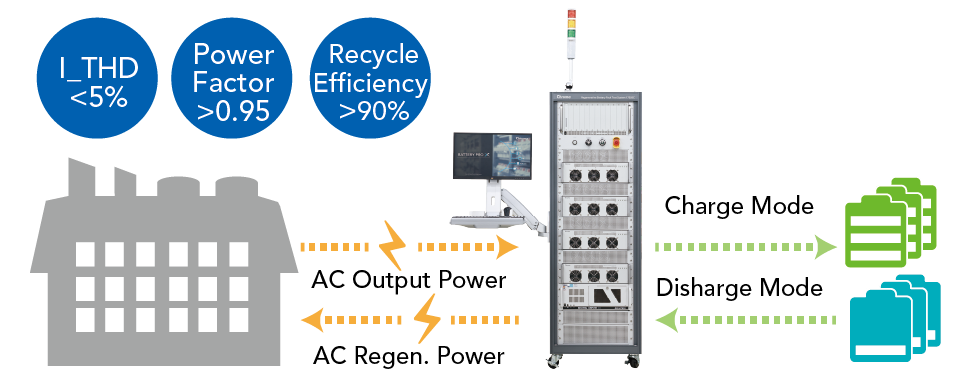

Recycled energy design

The system recovers the power released during the discharge of a battery module and sends it back to other battery modules in the charging channel or back to the utility grid, thus saving power and reducing heat generation.

Multiple independent channel design architecture

The system supports exclusive charge/discharge testing of multiple battery modules/packs, with independent test characteristics for each channel. Channels can be connected in parallel to meet higher current requirements, providing flexibility between high channel counts and high current testing.

Flexible Programming Functions

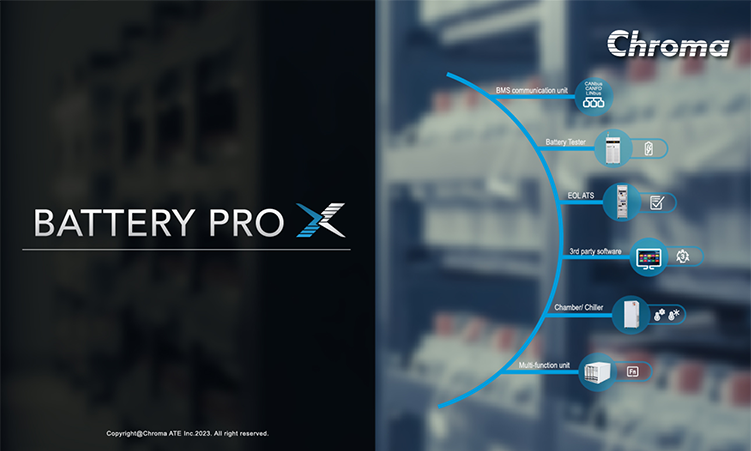

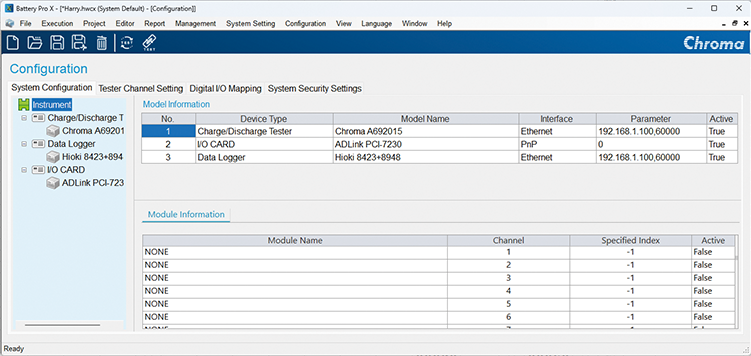

The Chroma 17020C system is equipped with "Battery Pro-X" software, which provides flexible programming capabilities and an intuitive and easy interface for editing and executing test steps. The system provides graphical test flow creation, predefined test templates, real-time data monitoring, and seamless integration with external devices, which significantly improves the efficiency and accuracy of test configurations and meets all kinds of complex test requirements.

Backup Battery Unit (BBU) / Rack Testing

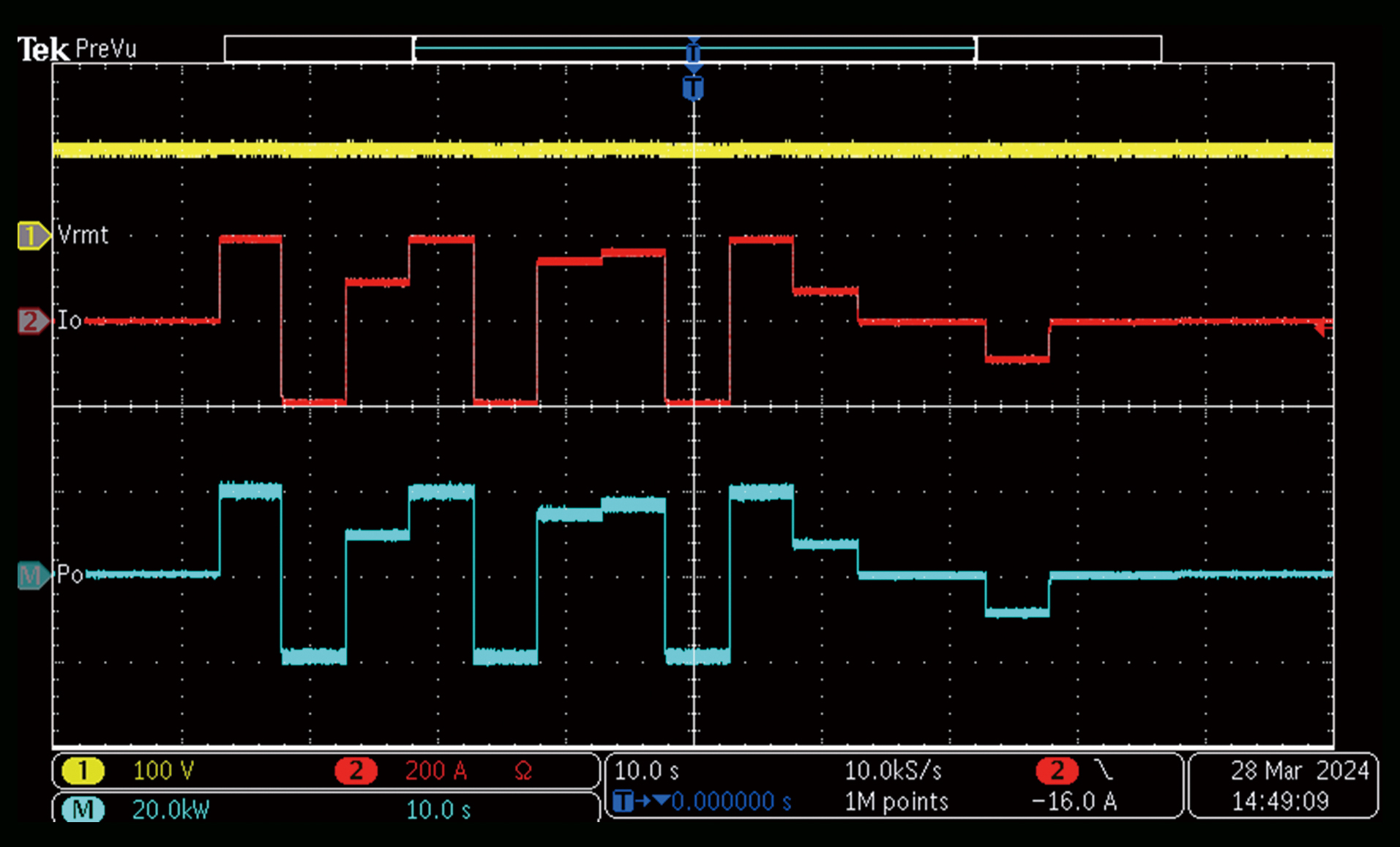

To ensure accurate BBU testing, the conversion rate of the test equipment must be minimized. with a ramp rate of 5ms (from 10% to 90%), the Chroma 17020C is the optimal solution for backup battery unit (BBU) and battery backup system (BBS) testing, providing precise control and reliable performance.

Current creepage rate

The system is equipped with a 10ms climb rate from -90% to +90%, which accurately simulates the driving state under dynamic driving conditions, ensuring the authenticity and reliability of the test results.

Safety Features

Multiple safety protection mechanisms are built into the system, including battery polarity checking, over-voltage protection, over-current protection, over-temperature protection and VDE-4105-AE islanding detection, etc., which comprehensively safeguard the safety of the testing process. The data saving mechanism can automatically store the data into the memory in case of computer abnormality or instantaneous power failure to avoid data loss and record the interruption status, which can be selected to continue the test after recovery. These features make the Chroma 17020C system an efficient and accurate all-round battery testing solution. Its flexible programming capabilities and intuitive operating interface make it easy to operate and fully meet the needs of different test scenarios.

System Features

- Two measuring ranges with precision accuracy

- Voltage range: 60V / 150V; Current range: 50A / 100A

- Voltage accuracy: 0.02%FS, 60V ± 12mV / 150V ± 30mV

- Current accuracy: 0.05%FS, 50A ± 25mA / 100A ± 50mA

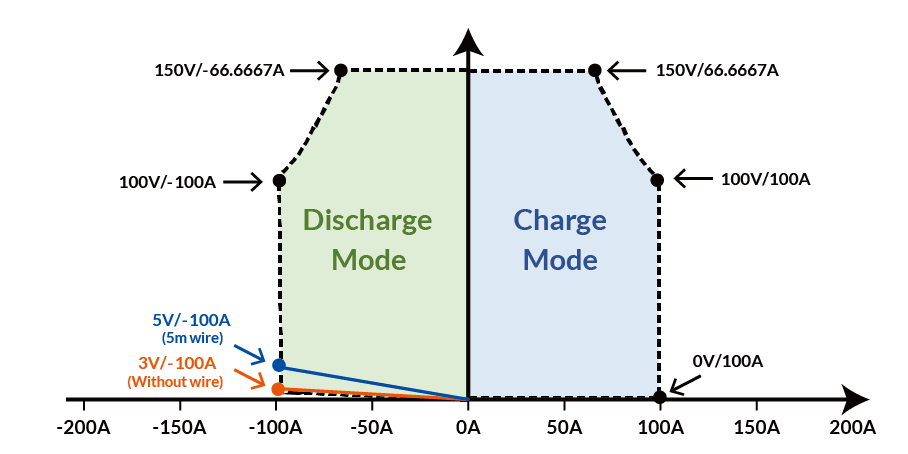

- Full current discharge

- Full current discharge at 3V, below 3V the discharge current decreases with voltage, 2V/-85A, 1.5V/-65A, 0.3V/16A.

- Smooth current transition (from discharge to charge cycle)

- Stabilized current, no surges during transition

- No current interruption when switching from charging to discharging

- operating mode

- Constant Current (CC)

- Constant Voltage (CV)

- Constant Power (CP)

- Constant Resistance (CR)

- Constant voltage-current limited charge/discharge mode (CC-CV)

- Constant power - current limited charge/discharge mode (CP-CC)

- Dynamic Arbitrary Current Waveform Mode Charge and Discharge Mode

- DC internal group detection DCIR mode, CV power mode

- standstill mode

- Recovery of battery discharge energy

- Recovery to grid or internal loads

- Low heat output reduces air conditioning power consumption and saves costs

- 17020C system has a total harmonic distortion (THD) of less than 5% at rated power

- Power factor (PF) greater than 0.9 at rated power

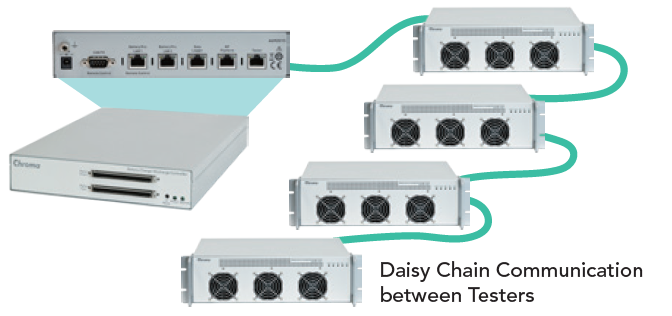

- Communications (CSU/charge/discharge tester)

- Fast and efficient data processing, no buffering of data, reduced latency network communication

- Connected with daisy-chained devices for real-time and accurate data exchange

- Minimum sampling rate of 10ms

- Protection conditions

- Over-charge voltage / Over-discharge voltage / Over-current / Over-temperature / Over-capacity / Loop resistance protection

- Reverse connection protection, line loss protection (ΔV)

- Δ protection: -ΔV / +Δ (voltage), +ΔI / -ΔI (current)

- Reporting data logging parameters

- move

- Testing time

- Real-time ID

- cyclicality

- circulate

- step mode

- step time

- Voltage (V)

- Current (A)

- Capacity (Ah)

- Energy (Wh)

- Cut-off voltage (V)

- Cut-off current (A)

- Cut-off capacity (Ah)

- DCIR (milliohms)

- Temperature (˚C)

- Fast current response for dynamic drive curve simulation

- Minimum rise rate of 5ms (10%-90%)

- Report logging interval of 10ms

- Dynamic charge/discharge power or current waveforms in accordance with NEDC, FUDS and HPPC standards

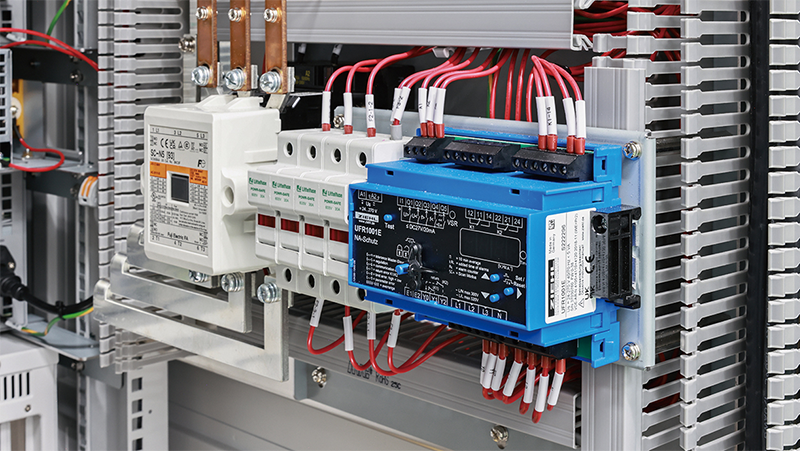

- Hardware Attachment Safety Features

▲Anti-islanding protection: VDE meter ufr1001e (optional)

▲ Output isolation monitoring: Instrumentation ISO685 (optional)

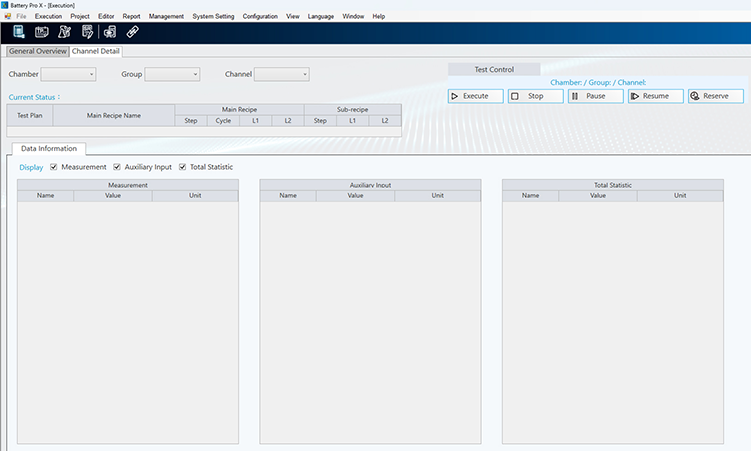

Graphical User Interface - BATTERY PRO X

Designed to meet the diverse needs of secondary battery pack testing, the 17020C test system offers excellent safety and stability. The system's charge/discharge protection mechanism will automatically abort the test when abnormal conditions are detected, ensuring the integrity of equipment and data. In addition, the system has a perfect data protection function, which can effectively prevent data loss caused by power failure, and support the safe storage and rapid recovery of data, providing users with reliable testing security.

Battery Pro X Main Screen

Charge/discharge test program editing screen

Real-time monitoring screen

- Work step editing

- List of 2-tier recipes

- 500 charge/discharge conditions can be edited

- Cycle & Loop function: each layer can be set for 999,999 cycles.

- Support dynamic charge/discharge waveform editing: with 10ms current switching speed

- Test Procedure: CV / CC / CP / CC-CV / Waveform Current / DCIR

- Cut-off conditions: time, current, capacity, cut-off voltage, cut-off current, etc.

- Conditional completion action: next/end/jump to a step to rest

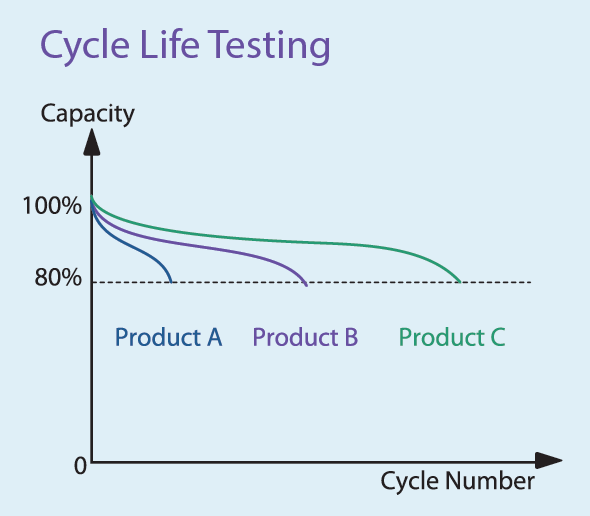

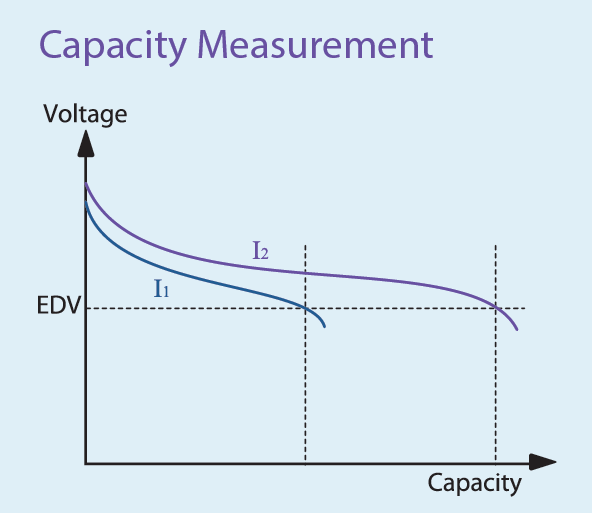

- Report Analysis and Statistical Report

- Produce detailed reports and step-by-step reports

- Customize report formatting, export PDF, CSV and XLS file formats

- Graphical report function

- Report analysis function, user can create customized reports by customizing X-axis and Y-axis parameters, such as life cycle report, Q(AH)-V(V) report, V(V)/I(A)/T (℃)-time report, etc.

- Instantly view test reports for each channel

Hardware configuration

- Multi-function rack with BMS socket port

- AC/DC Bidirectional Converter

- Recycling Charge/Discharge Tester (69210C)

- Industrial computer (optional)

- Status Indicator Tower Light

- Rack Arm Monitor (with Keyboard Holder)

- Data Logger Placement (Optional)

* :: Support customization requirements for other equipment

Product Features

- Charge/discharge mode (CC, CV, CP)

- Power range: 10kW to 80kW per channel, can be extended by modules by 10kW per module

- Voltage range: 150V

- Current range: 100A per channel and can be paralleled up to 800A

- Battery discharge energy recovery function, efficiency 90%

- Saving electricity, protecting the environment and reducing costs

- Low heat and noise output

- Charge/discharge efficiency: 95%-97% (>5% rated power)

- Standby loss: 2.56W per channel

- Parallel control of channels: controlled by software

- Driving cycle simulation: with 5ms rise rate, ranging from 10% to 90%

- High resolution measurement: 18 bits

- Smooth current transition: smooth and uninterrupted between charging and discharging, without surges

- Test Data Analysis: Reporting Data and Graphical Presentation

- Data recovery protection: support power failure data resumption function

Application Areas

- Electric Vehicle Battery Module

- Electric Motor Vehicle Power Battery

- Electric Bicycle Batteries

- UPS battery

- Energy storage batteries

- Power Tool Battery

- starter battery

- lead-acid battery

| model number | relate (a story or information) |

| 17020C | Energy Recovery Battery Module Test System |

| 17020C | Energy Recovery Battery Module Test System 10kW, 150V |

| 17020C | Energy Recovery Battery Module Test System 20kW, 150V |

| 17020C | Energy Recovery Battery Module Test System 40kW, 150V |

| 17020C | Energy Recovery Battery Module Test System 80kW, 150V |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.