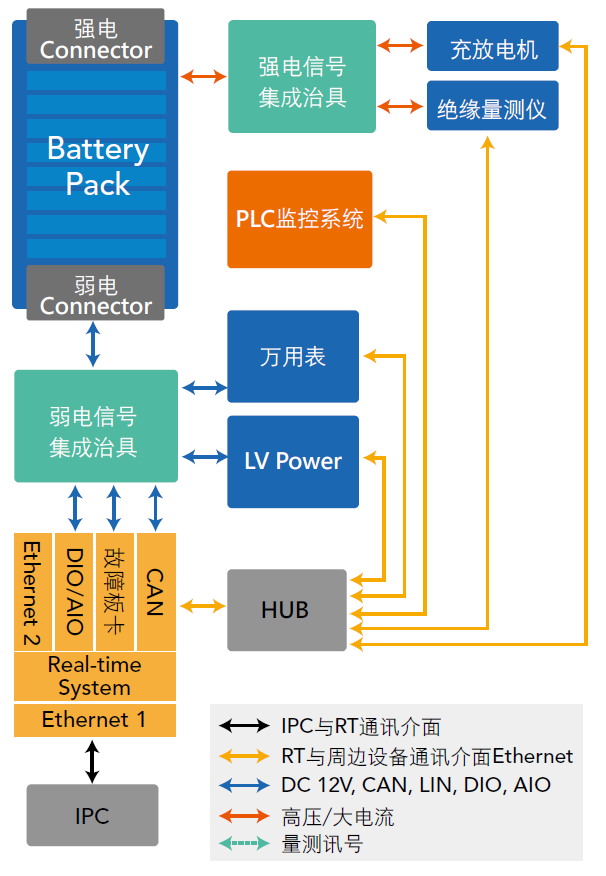

Chroma has launched a new battery pack power stage hardware-in-the-loop test bench system, which is capable of testing new energy vehicle battery systems and their components, including battery modules, battery management systems, and heat dissipation and cooling systems, and provides a variety of hardware choices for integration, such as DC power supplies, battery chargers and dischargers, digital meters, insulation meters, and short-circuit and over-voltage protection devices.

Chroma 8610 Battery Pack Power Level Hardware-in-the-loop Test System is specially designed for the research and development of battery modules and battery packs, combining real-time hardware system and open software architecture to provide users with a flexible and powerful dynamic test system, which can be imported into the actual vehicle conditions for charging and discharging, CAN signal measurement and control, fault injection, insulation measurement, and simulation of charging piles charging and other related test projects, and can be used for the simulation and verification of the most important compound working conditions and the highest risk of failure compound operating conditions (e.g., communication and physical signal failures during cyclic discharge). The platform can be flexibly arranged and combined to simulate and verify the most important compound working conditions in the vehicle environment and the compound operating conditions with the highest risk of failure (e.g., communication and physical signal failures during cyclic discharging), so as to conduct more in-depth tests on battery packs without the need to test in the actual vehicle, and to significantly improve development efficiency.

The 8610 system integrates Chroma's own high-performance 170X0 series battery charger/discharger to simulate the power system's action of pulling and recharging the battery packs, which can be used to simulate the fast dynamic charging and discharging behaviors of the battery packs in different vehicle driving conditions, in addition to increasing the reliability of the validation and having the ability to test the whole vehicle level. In addition, the power output from the battery pack during the testing process can be fed back to the power grid through the Chroma charger/discharger to increase the efficiency of energy utilization and help save costs.

Support vehicle development process and functional safety testing needs

▲ Fault Injection Function Operation Interface

Chroma 8610 Battery Pack Power Level Hardware-in-the-Loop (HIL) test system not only realizes the basic functional and signal control tests, but also includes the actual power behavior verification. Compared with the traditional signal level HIL solutions, 8610 system covers the test scope of EV high power components more completely. The 8610 system helps users to conduct more validation work for battery packs, battery modules, battery management systems, and heat dissipation and cooling systems at the right end of the standard V-type development process, including battery pack system-level functionality and a variety of composite operating conditions, so that problems can be detected and errors can be corrected at an early stage prior to entering vehicle testing, effectively reducing development costs and improving testing efficiency.

In order to cover the complex behavior of the actual operation of various vehicles, in recent years, the vehicle industry has been vigorously promoting ISO 26262 road vehicle functional safety specification as a standard to be followed by vehicle manufacturers and their suppliers in product development. ISO 26262 is expanded from the product system down to the hardware and software, and puts forward the content that should be followed in order to meet the safety requirements (Functional Safety Requirements→Technical Safety Requirements→Hardware Safety Requirements→Software Safety Requirements). (Functional Safety Requirements → Technical Safety Requirements → Hardware Safety Requirements → Software Safety Requirements), and in the testing and verification section, it is mentioned that regardless of any functional safety integrity (ASIL) level, hardware in the loop and fault injection tests must be conducted to ensure that the safety mechanism is correct at the level of the entire vehicle and the effectiveness of the failure coverage.

The 8610 integrates a Fault Injection Unit to conduct arbitrary open and short circuit fault tests for various control and communication signals of the system under test, and can be combined with dynamic discharge, insulation impedance changes and static charging... and other vehicle behavioral simulations to simulate and validate the most important composite operation scenarios of the vehicle with the highest risk of failure, so that more in-depth tests can be carried out on battery packs without the need for a real vehicle. In-depth testing of battery packs without the need for a real vehicle helps to improve the ISO 26262 process of fault injection test content, which is conducive to obtaining ASIL safety level certification.

Realize instant control, data acquisition, communication and protection functions

Chroma 8610 system has over-current protection, over-voltage protection, under-voltage protection, short-circuit protection, temperature monitoring and other alarm functions and protection mechanisms, and its control software is an open architecture, which can be synchronized with the real-time system, power equipment, measurement modules and simulation models for vehicle-level Real-time dynamic testing of battery packs.

The communication interface supports the commonly used CAN, CAN FD and LIN interface protocols, and has the function of loading the DBC file required for CAN communication. The manual test is equipped with highly flexible editing and modification of the human-machine interface, allowing the user to continuously optimize the test items and processes; while the automatic test supports ASAM XIL as the interface to the upper test software, and records the system's various monitoring parameters after the completion of the automatic test procedures for subsequent analysis.

The test interface can set the data acquisition time, in addition to instantly displaying the value of each parameter (speed, voltage, current, input power, output power, efficiency, temperature, operating mode, etc.), and in the test process will be for the parameters of the graph and the output of the report.

Another configuration of independent PLC monitoring system, instantly monitor the system software and power equipment operating status, if there is an error state occurs can immediately stop charging and discharging behavior, instant protection of products and equipment systems.

Highly flexible and intuitive human-machine interface

Human-machine interface (UI Interface) for the test system is a very important link, will directly affect the R & D testers ease of operation and test execution efficiency, Chroma 8610 system can be customized for the user to plan the content of the required functions, and the integration of a variety of instruments and equipment, the establishment of the control and test program development environment for the user to write, modify the test program and allow the user to edit and modify the UI screen. Users can write and modify test programs, and allow users to edit and modify the UI screen. The main functions include:

Display of equipment and DUT parameters

Such as battery charging and discharging status, voltage, current, power, electricity, protection alarm, insulation degree,⋯, etc., and can be instantly updated with numerical, instrumentation and graphical changes.

The control parameters to be set for the test program

Such as battery charging and discharging start-up and shutdown, charging and discharging voltage, current, power setting, insulation measurement start-up, fault injection signal selection, test condition selection, etc., and can change the control value by digital, drag and switch.

▲ Battery charging/discharging setting and monitoring operation interface

Vehicle grade dynamic charge/discharge and composite condition applications

With the Chroma 170X0 series battery charger/discharger, the 8610 can simulate the dynamic pulling and recharging behavior of the power system on the battery pack, and support Altair Activate vehicle models and various Simulink Model-Based real-time mathematical model import, through the NEDC, WLTP and other international standard vehicle driving cycle to achieve the whole vehicle level battery dynamic charging and discharging performance verification. Cycle realizes dynamic battery charging and discharging performance verification for the whole vehicle. Compared with general battery test systems, it does not need to obtain the charging and discharging records of the actual vehicle operation and load and play them back at once, so that it can directly realize the instant battery pack dynamic test function. In addition, it can also combine signal measurement and control, fault injection, insulation measurement, and simulated charging at charging piles to achieve complex working conditions for more in-depth testing of the test object. The following is an example of charging and discharging after loading a real vehicle and simulating a fault injection to instantly change the charging action.

Multiple test items

Single test function

(1) Constant current and constant voltage charge/discharge test

(2) Vehicle Driving Cycle Loop Discharge

(3) Arbitrary Charge-Discharge Pattern Reproduction

(4) Voltage Measurement and Differential Voltage Detection

(5) Current measurement and current difference detection

(6) Up and down control logic and timing (relay self-test mechanism confirmation)

(7) High voltage interlocking mechanism

(8) Battery protection function timing check

(9) Dynamic leakage current

(10) GB/T, CHAdeMO, CCS DC charging and interoperability tests

(11) Dynamic leakage current

(12) Insulation impedance measurement

Composite Test Function

(1) In case of Driving Cycle loop discharge, fault injection detection and confirmation of insulation and voltage resistance level.

(2) Arbitrary discharge and recharge pattern reproduction, fault injection detection and confirmation of insulation and voltage resistance degree

(3) Impact of fault injection on power calculation and various protection functions

(4) Fault injection detection and confirmation of insulation and voltage resistance during AC/DC interface charging.

(5) Battery power, cell and total voltage, fault signal and charging energy change relationship test

(6) Charging full power correction mechanism test

(7) Automated endurance dynamic operation test combining programmable temperature chamber and energy consumption model of the object to be tested

Product Features

- Integrate on-the-fly control of Fault Injection Unit hardware for fault injection function simulation to help improve ISO 26262 functional safety testing.

- Supports various Simulink Model-Based real-time vehicle model importing, and realizes dynamic charging and discharging performance verification of vehicle-grade batteries through international standard working conditions such as NEDC and WLTP.

- Supports CAN, CAN FD, LIN, RS-485 communication interfaces

- Instant monitoring of timing related to battery high voltage relay open/close, initial power output, CAN signals, etc.

- Versatile, modular hardware provides test accuracy and repeatability and can be expanded to meet user needs

- Upper layer automated test software support via ASAM XIL and ASAM XIL-MA

- Independent PLC system instantly monitors and controls to ensure the safety of the test process.

- Integration of DC EVSE charging interface, including CAN, PLC communication and related control signals, to meet different charging specifications required for compatibility testing.

- Hi-Pot test equipment can be integrated to measure battery insulation and grounding status.

Applications:

- Battery Pack System Calibration and Verification

- Reliability and durability testing

- Simulated vehicle driving conditions test

- System Integration Testing

| model number | relate (a story or information) |

| 8610 | Battery Pack Power Level Hardware-in-the-Loop Test Bench System |

| 17020 | Battery charger/discharger |

| 17040E | Battery charger/discharger |

| 62000L Series | DC Power Supply |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.