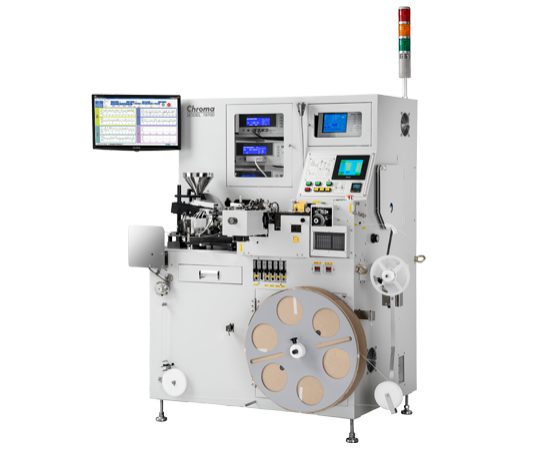

Chroma 1871 is an automated test production equipment designed for chip type inductors, especially designed for interlayer short circuit test to meet the mass production requirements of clients.

The test function of the 1871 is the inter-wrap short circuit test (IWT), which is a test system to check the quality of chip inductance. The system also inherits all the judgment functions of the Chroma 19301A Wirewound Component Pulse Tester, including Area, Laplacian, and the new judgment functions of Δ Peak Ratio and Δ Resonant Area.

In response to today's electronic products, thin inductors are being used in large numbers, which in turn requires mass production. The Chroma 1871 has a maximum production rate of 1,500 units per minute to meet the huge capacity requirements. The Chroma 1871 utilizes a 5-group interlayer short-circuit test station to achieve rapid mass production. Alternatively, the Chroma 1871 can be used with only 2 sets of interlayer short-circuit test stations for R&D or QA units that do not require mass production, for optimal cost-effectiveness.

The 1871's feeding module utilizes a disc vibratory feeder to deliver thin products at high speeds. The disc vibratory feeder can control the direction of the product during feeding through the rail design, fiber optic detection and air blowing through the air holes, which is faster and less space-consuming than the previous linear reciprocating mechanical feeder.

Traditional reciprocating or turret type mechanical structure in the test of transfer, the suction nozzle is used to adsorb and transfer the product, often due to the impact of mobile inertia during the transfer of the product fall or positioning inaccurate measurement. 1871 test area for the design of the closed guide plate structure, high-speed transfer will not have the product fall when the suspicion of faster and more stable compared to the traditional mechanical structure.

ChipMOS specializes in precision electronic measurement technology, and the fixtures for automatic test equipment can also be customized. 1871 uses a four-wire type measurement design for the test holder, and the connection between the test holder and the product adopts a chip-type design, which makes it easier to make contact with and has a longer service life than the probes used in general test equipment; the chip-type design is also more stable than the probes and is easier to maintain during the measurement process.

Chroma 1871 is equipped with specialized software to monitor the test status in real time during the production process and to collect and store the test data of each single product. The real-time monitoring function helps to reduce production risks and unnecessary man-hours; the data collection function can assist R&D and QA units to do product analysis or quality control, and the data analysis through the software interface can improve quality and increase profits.

Applications

R&D and QA batch validation with 2 sets of interlayer short-circuit test stations only.

R&D and QA units conduct product characterization tests to analyze product defects with layer-to-layer short-circuit testing. Therefore, it is also necessary to collect test data to analyze the data and quality of the product.

High-speed test production line with 5 sets of interlayer short-circuit test stations

The production line can be equipped with 5 sets of interlayer short circuit test stations, which can shorten the test time to achieve high-speed mass production, and monitor the test status and collect data at the same time.

| model number | relate (a story or information) |

| 1871 | Inductance interlayer short circuit automatic test system |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.