In recent years, as components become more complex and multi-channel and other complex issues, manufacturers in the test end of the cost and increase, in order to help manufacturers effectively reduce the cost of testing and product risk, the 8800 Component Automated Test System was born. 8800 Component Automated Test System can be done in a single test program to complete the measurement and test functions. This powerful function not only saves time, but also reduces human errors. Reduce the risk of improper testing, combined with open software architecture, to provide users with flexible, powerful and cost-effective automated test system to meet the use of comprehensive component testing program.

The 8800 Component Automatic Test System can integrate different test instruments into the system according to different test requirements. The software is fully open architecture, according to different test procedures, different products can provide corresponding programs, giving customers the most flexible test combinations. It also provides users with the function of expanding test items, so that if there are new requirements, they can edit the test items they want from the test item editing function.

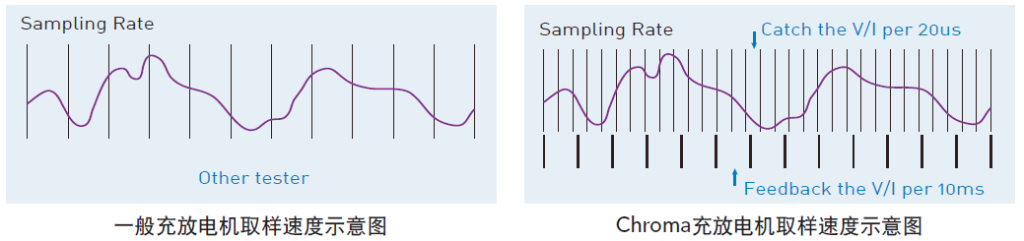

This automatic test system uses the unique perfect test command technology to avoid repetitive control commands being sent to the system hardware device, which significantly improves the test speed and makes the 8800 as efficient as a closed or optimized automatic test system despite the open software architecture, constituting a highly efficient and perfect component automatic test system. The special test editing function provided by this system allows users to create new test items according to their own needs, and also gives users the ability to expand the test database.

The system's open architecture software also includes statistical analysis and management capabilities. These features enable the system to generate a wide variety of test files and perform system management. The statistical reporting functions provided by the system are indispensable, which is extremely important for quality assurance and production testing in modern factories. The Chroma 8800 Component Automated Test System is designed to work with Windows R 2000/XP and above, providing test engineers with an easy-to-learn window environment and allowing the use of system resources provided by Microsoft.

The 8800 Component Automated Test System offers a wide range of hardware options for integrating different test instruments into the system according to different test requirements. For example, Chroma 13001 component test scanner can provide multi-channel scanning function, with Chroma 3302/3252/11022/11025 LCR meter to do inductance, capacitance, resistance and other measurements, and includes turn ration (turn ration) measurement (if the LCR meter has to provide this function), can also be used with the Chroma 11200 Capacitance leakage current/insulation resistance meter with insulation resistance test, and has a short circuit design for leakage inductance measurement.

8800 component automatic test system Chroma 13001 component test scanner with optional A113007 40 Channels scanning module, a single 13001 component test scanner can be up to 320 channels. 8800 in addition to 13001 component test scanner can be connected to the mainframe control, and can also be expanded up to 8 Chroma 13001 controlled The 8800 can be connected to the 13001 Component Test Scanner Control Unit, and can be expanded with up to 8 Chroma 13001 Controlled Units for up to 2880 channels to meet customers' needs for more channels.

Chroma 8800 component automatic test system, provides multi-step test program to meet the diverse test applications, such as RJ-45 devices (including LAN Modules, Ethernet IC, PoE IC, etc.), glass substrates (including solar panels), LCD glass substrates, glass printed circuits (including touch screen touch panel, etc.), PCB, circuit boards, EMI Filter, rechargeable battery test, ICT applications and other applications test customers, PCB, circuit board, EMI filter, rechargeable battery test, ICT applications, etc. Chroma 8800 component automated test system provides process control and data collection. With automation, it can save labor costs, reduce human errors, improve data management and quality and efficiency.

Product Features

- Open Architecture Software Platform

- Supports augmentation hardware

- Support for instruments with GPIB/RS-232 or RS-485 interfaces

- Test Item Edit Function

- Test program editing function

- Statistical analysis report function

- User Authority Setting

- Test item/program control function

- Personnel access system records

- Support Bar Code Reader

- Test command editing to help improve test speed

- Extensive modular hardware for highly accurate and repeatable measurements

- Increased test productivity through systematic test programs

- Optimal cost-benefit ratio

- Expandable hardware based on user requirements

- Graphical interface Windows® 2000/XP operating environment

*The test program can be prepared according to the user's need for different styles of substances to be tested.

Product Applications

- RJ-45 device testing (including LAN Modules, Ethernet IC, PoE IC, etc.)

- Glass substrate testing (including solar panels)

- LCD Glass Substrate Testing

- Glass printed circuit testing (including touch panels)

- PCB Testing

- EMI Filter Testing

- Rechargeable Battery Test

- ICT application

| model number | relate (a story or information) |

| 8800 | Component Automatic Test System |

| LCR Meter | 11022, 11025, 3302, 3252 series |

| Scanner | Component Test Scanner: 13001 |

| Scan Module | Refer to Model A130007 Series |

| IR Meter | Capacitance Leakage Current/Insulation Resistance Meter: Model 11200 |

| A800005 | PCI Bus GPIB Card (National Instrument) |

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.

Comprehensive test and measurement service provider-Shenzhen Weike Electronic Technology Co.